|

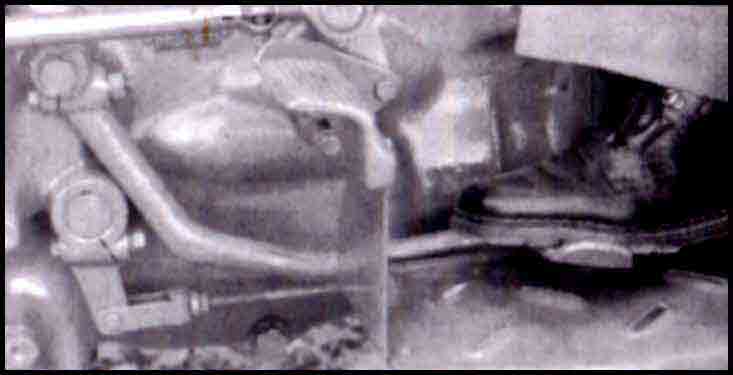

Always use uncontaminated diesel; i.e. that does not contain sand, water, kerosene, and other unnecessary elements, because these ruin the costly and delicate parts of the fuel injection pump and automizer which deteriorate engine performance. To protect the parts described and described above, it is important that you refill the diesel tank after completion of work. Refilling the tank will decrease air in it. The less air in the tank will create fewer water vapors, and the parts will be safe from harm. Never mix oil in the diesel. Diesel Inlets |

|

|

|

|

Massey Ferguson-260

|

Massey Ferguson-240/350

|

|

|

|

Massey Ferguson-375/385

|

Massey Ferguson-375/385 4WD

|

Tractor Care Tips

Storing the Diesel

|

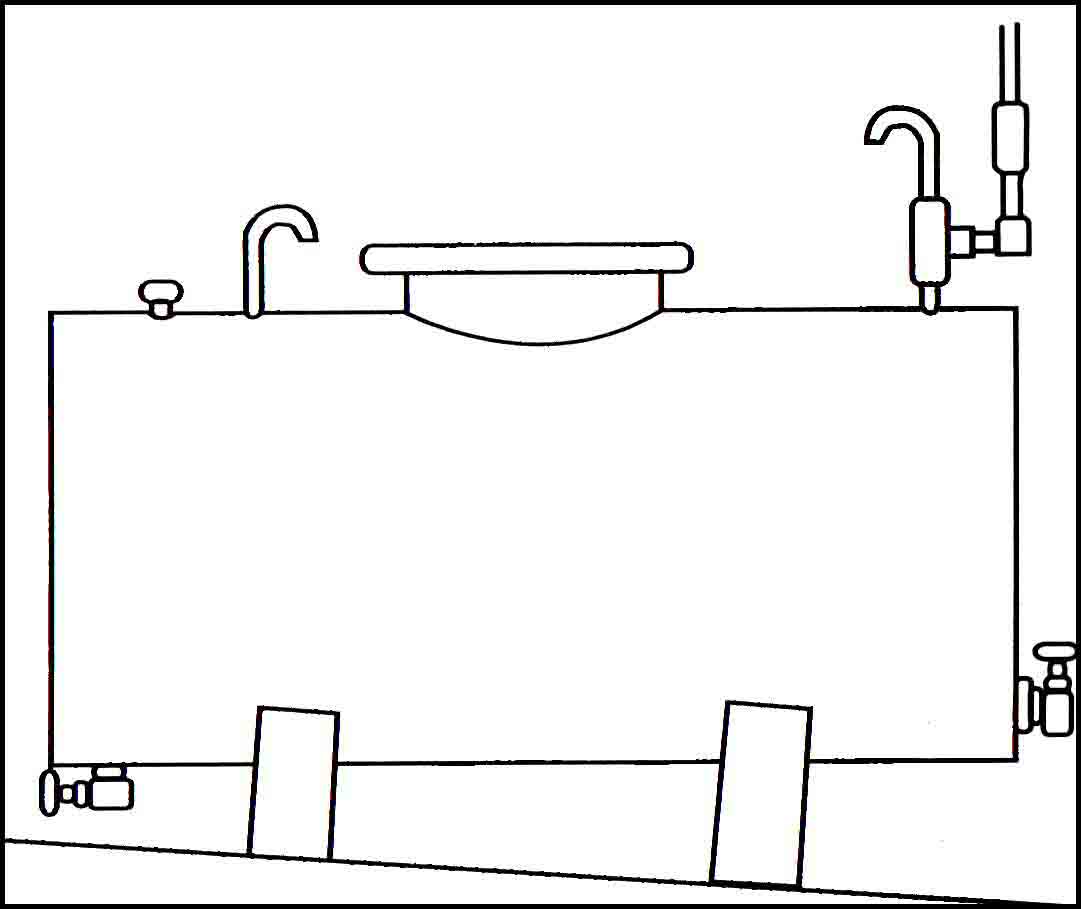

If diesel is to be stored in drums, then tilt the diesel filled drums as shown in the picture below. Front end of the drum must be 3 to 4 inches higher than its rear end, so that all unwanted deposits like sand, rust, dust settle at the back end, and clean diesel comes out from the front.

|

|

|

Storing the diesel on smaller scale

|

|

|

Storing the diesel on a larger scale

|

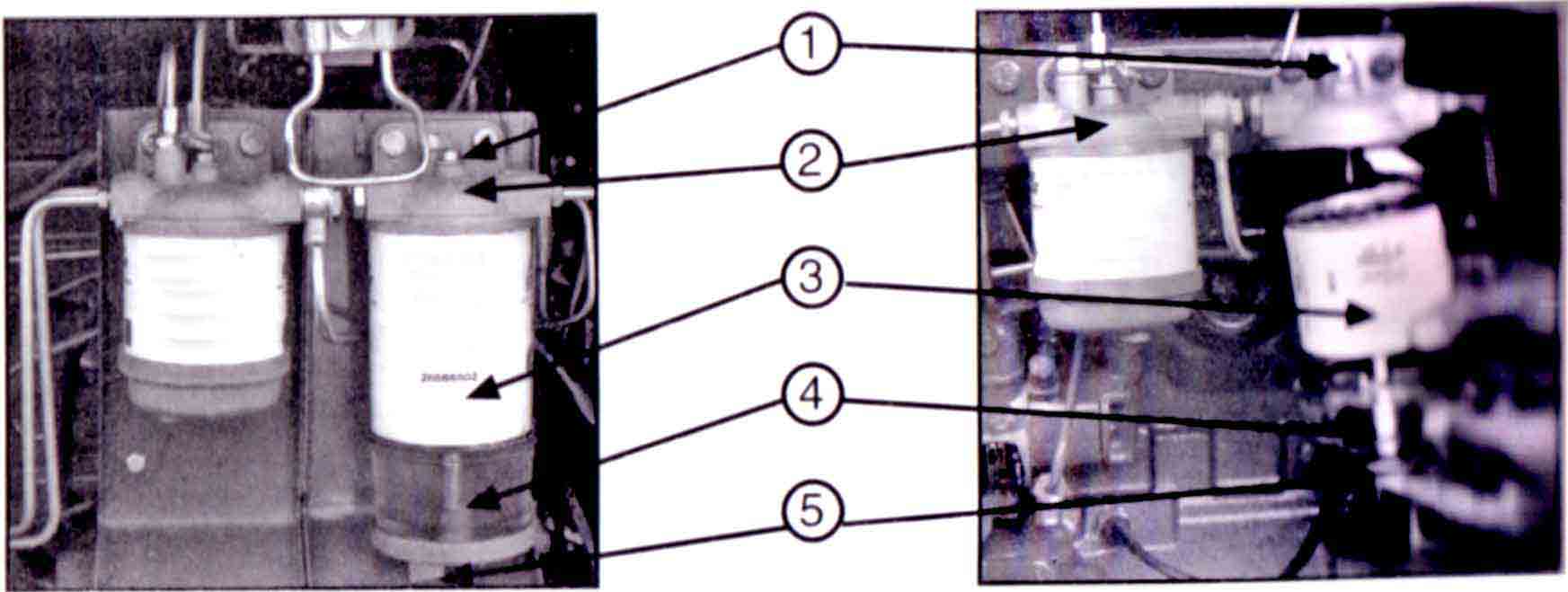

How to Change the Diesel Filter in Tractor

| Very Important Change the diesel filters regularly on timely basis and use only genuine filters. Never use polluted oil. | ||||

|

||||

| 1) Center bolt | 2) Filter head | 3) Filter | 4) Glass cup | 5) Drain tap |

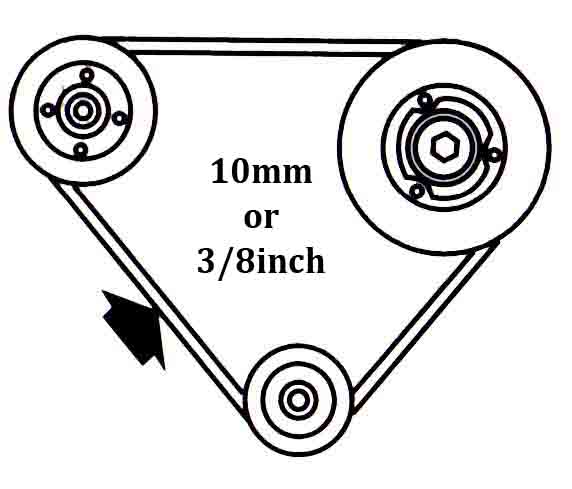

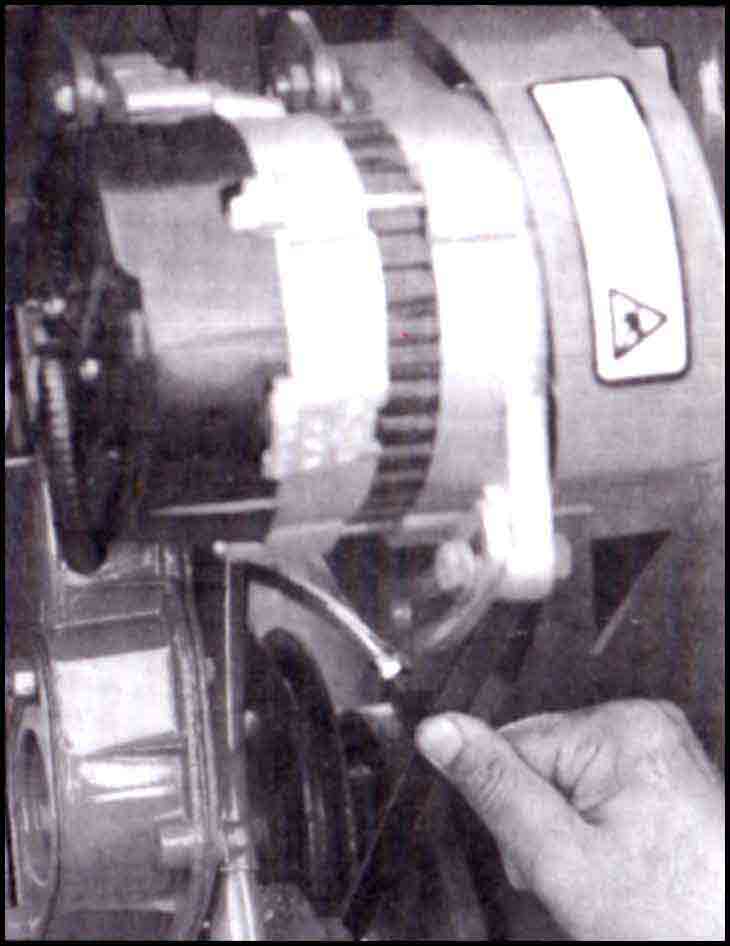

Checking the Fan-Belt Tension of MF Tractor

|

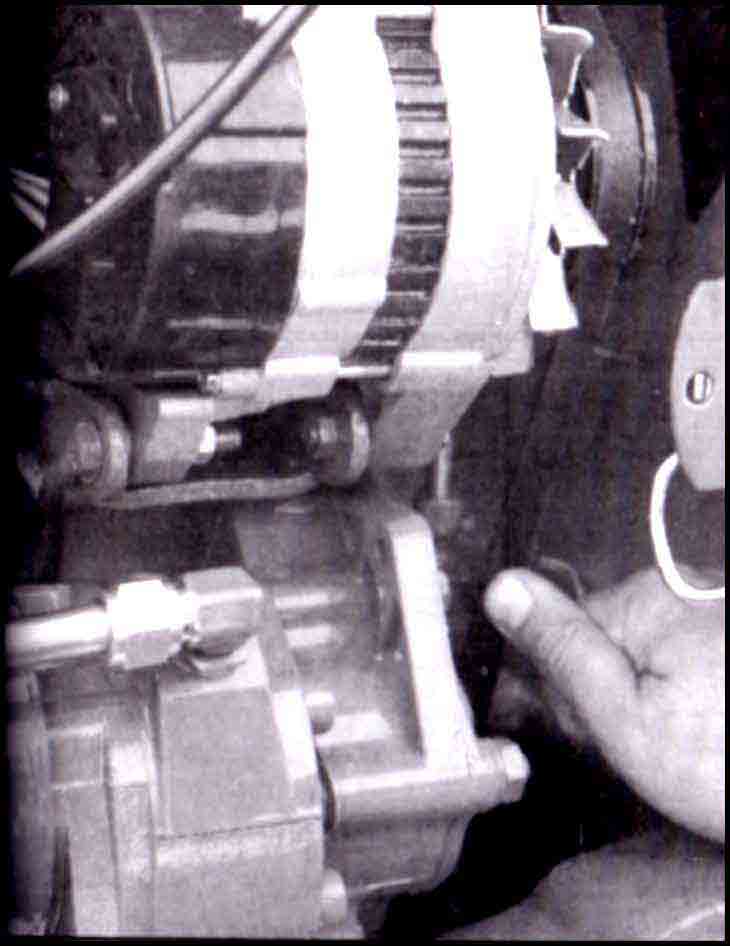

Fan-belt being loose or overly tightened may become a reason to overheat the engine and damage the alternator. Therefore, it is necessary to have the fan-belt tightened to proper tension. To check the tension, pressing the longer portion of the belt (between the alternator and crankshaft pulley as shown in the picture) with a force of approximately 10 pounds should loosen the belt 10mm or ? of an inch. In case of improper tension in the belt, loosen the alternator and adjusting link nuts, and by pressing the alternator with the help of a lever, tighten the bolts after adjusting the belt’s tension. Check the tension again after tightening the bolts. |

|

| Very Important Always use belts of correct size. Do not use any kind of oil or grease to mount the belt. |

|

|

|

|

Fan belt MF-240/350/260

|

Fan belt MF-375/385/385 4WD

|

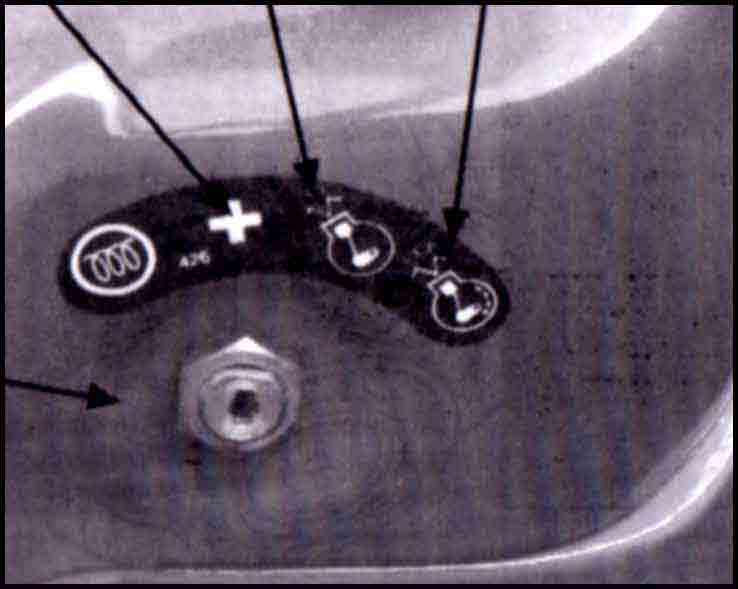

How to Start the (John Deere/ New Holland/ Massey Ferguson) Tractors

| Press the engine shutting off lever (choke) as far as possible Keep both levers in neutral position Insert key in the ignition at position number 1 Turn the key clockwise to the position number 2, which will turn ON the entire electrical system and all the gauges and meters will start functioning Turning the key to the position number 3 will start the engine. Release the key as soon as the engine starts Before HEAT starting the tractor, turn the key counter-clockwise; then after 15 to 20 seconds turn the key clockwise to the start position NEVER start the tractor with any other key or engine dipstick. |

How to Shut-Off the (John Deere/ New Holland/ Massey Ferguson) Tractors

| Press the clutch and put all gears into neutral position Pull out the engine shut-off lever (choke) to its maximum limit, engine will shut off Bring the key back to position number 1, which will cause all meters and gauges to stop functioning. Then remove the key from ignition | ||

|

|

|

|

Key Ignition

|

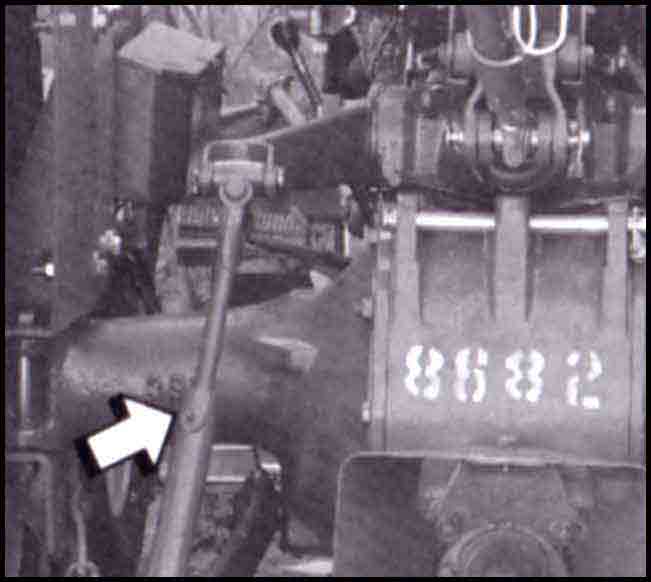

Choke MF 240/350/260

|

Choke MF 375/385/385 4WD

|

Very Important (FOR TURBO ENGINE)After starting, keep the engine running for 2 to 3 minutes at low idle speed. Before shutting off, keep the engine running for 2 to 3 minutes at low idle speed. Never press the accelerator immediately after starting or before shutting off the engine. |

||

Engine Temperature of John Deere/ New Holland/ Massey Ferguson Tractors

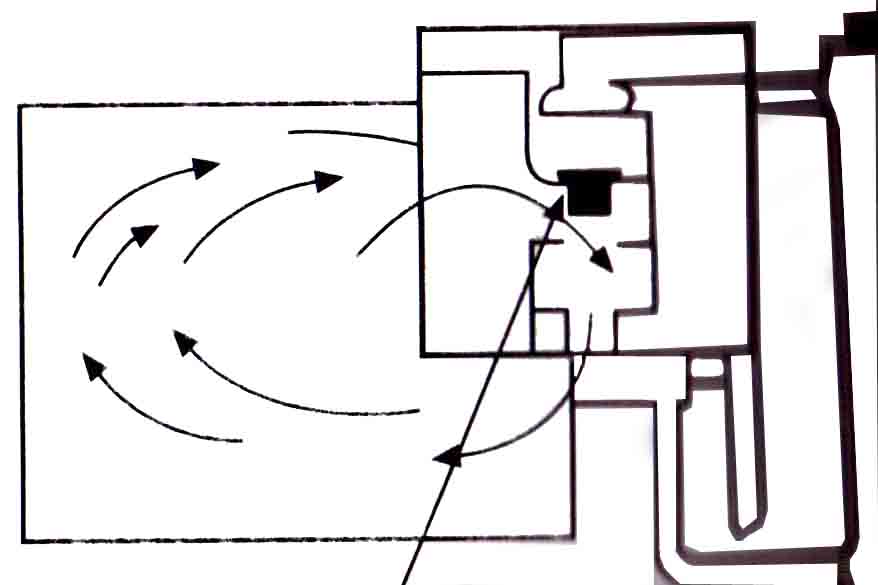

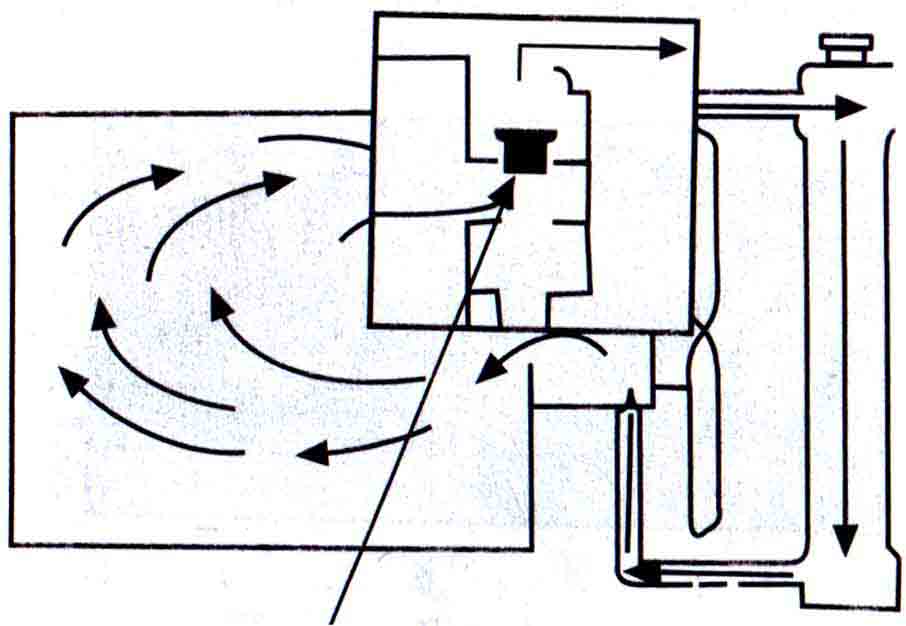

The designated temperature of diesel engine is 80 to 85oC. To maintain this temperature, there is a valve called ‘thermostat’ in the engine. Never detach it from the tractor under any circumstance. Engine parts have been manufactured to operate at a specific temperature, and the engine may be harmed if the temperature falls under or rises above this temperature. Commonly the inexperienced or ill trained mechanics remove this valve from the engine, which cause the engine to operate at cold temperature. Engine operation at low temperature causes faster wear out of the piston rings and liners, and soon the engine becomes useless. Experiments have demonstrated that operating the engine at 40o C instead of 80oC wears out the piston rings twice as fast. Meaning, the service repairs commonly need after four years becomes necessary after just two years. Moreover, the cold engine operation increases the diesel consumption by 5%.

|

|

|

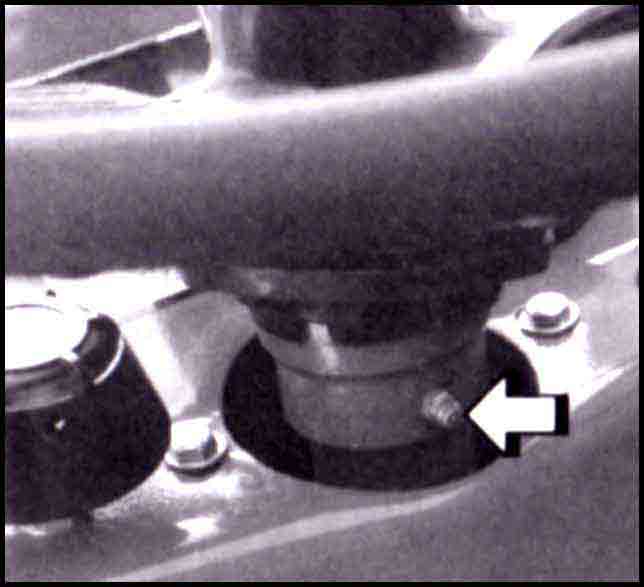

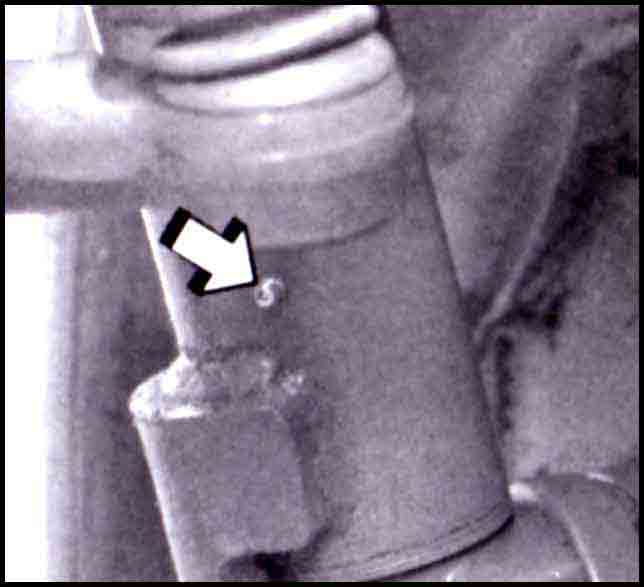

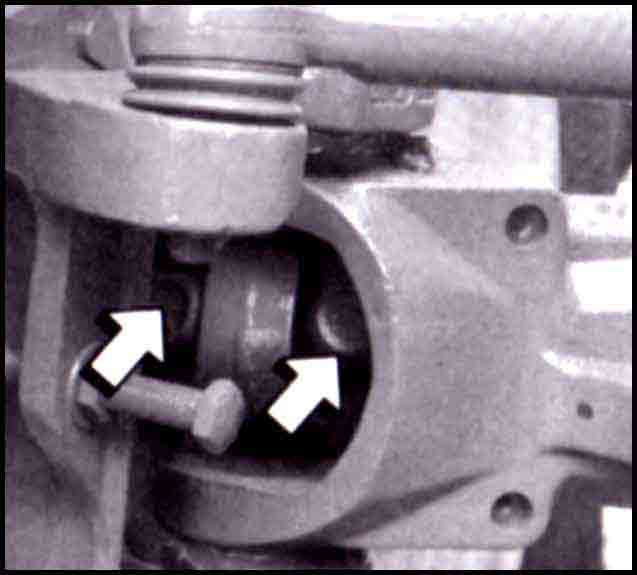

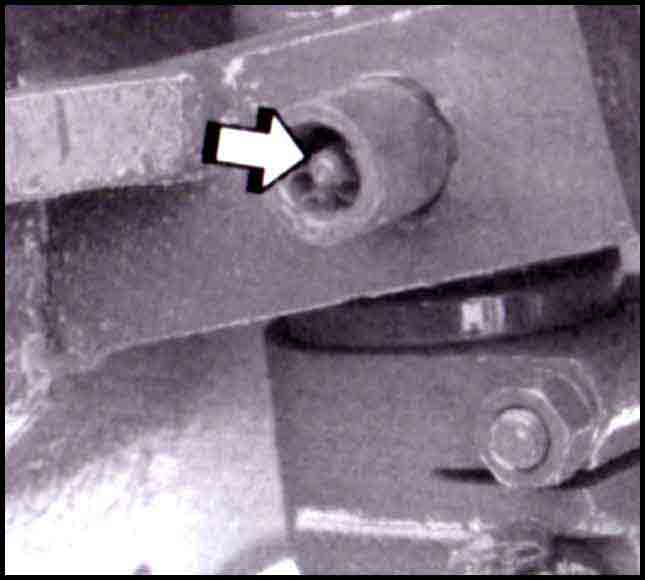

Thermostat valve MF-240/350/260

|

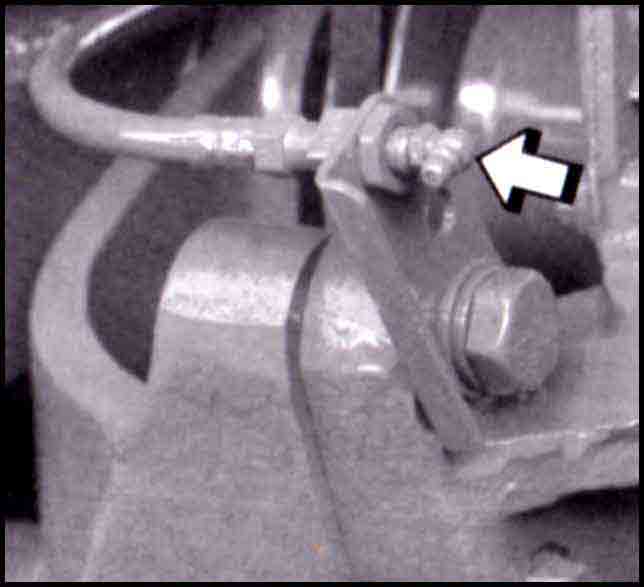

Thermostat valve MF-375/385/385-4WD

|

|

|

|

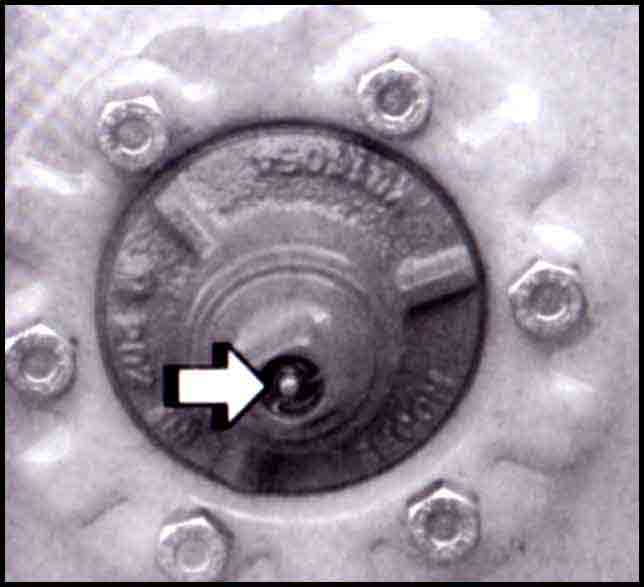

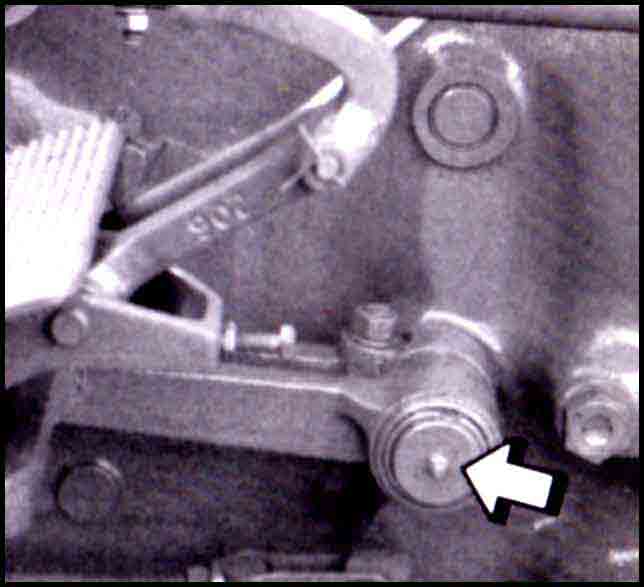

The valve is close due to engine being cold

|

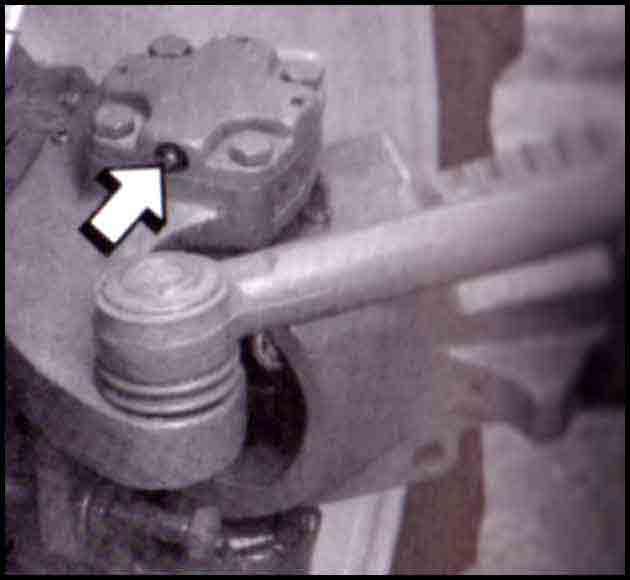

Valve is open when the engine is warm at the prescribed temperature

|

Method of Running-in and Driving the Tractor

Very Important Under no circumstance operate the tractor empty (without load), nor keep the engine running idle for long periods of time. How to Operate the Tractor

|

|

|

|

Clutch Pedal MF-240/260

|

Hand Brake MF-240/350/260

|

Before starting the tractor daily

Every Week check before starting the tractor…

VERY IMPORTANT If any of the aforementioned have not been done, leave everything and complete the measures before starting the engine. |

|

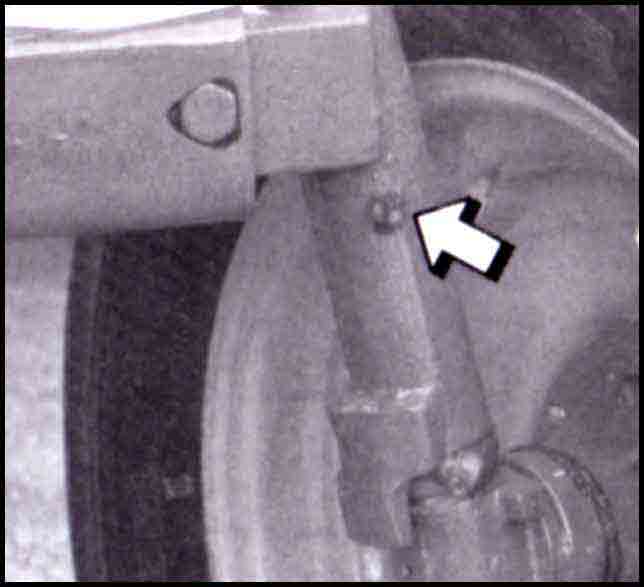

Grease Points on (MF) Massey Ferguson Tractors

|

|

|

| Steering Column MF 240/260/350 | Bearings on Front Wheels MF 240/350/260/375/385 | Front Spindles on both sides MF 240/260/350 |

|

|

|

| Front Spindles on both sides MF 375/385 | Front axle Pivot Pin MF 240/350/260 | Brake Pedal Bush MF 240/260 |

|

|

|

| Front axle MF 385 4WD | Front axle MF 385 4WD | Steering Pivot pin MF 375/385 |

|

|

|

| Left Linkage point MF 240/350/260/375/385 | ||