Whether you’re tending vast fields in the heart of Gambia or maintaining a small farm on its outskirts, your tractor is likely central to your agricultural activities. It’s the powerhouse that makes modern farming feasible, but like all machinery, it’s prone to occasional hiccups. Fortunately, many common tractor problems can be diagnosed and remedied with a bit of know-how. In this guide, we’ll explore some typical issues tractor owners might encounter and offer advice on how to resolve them.

Common Tractor Issues and Solutions

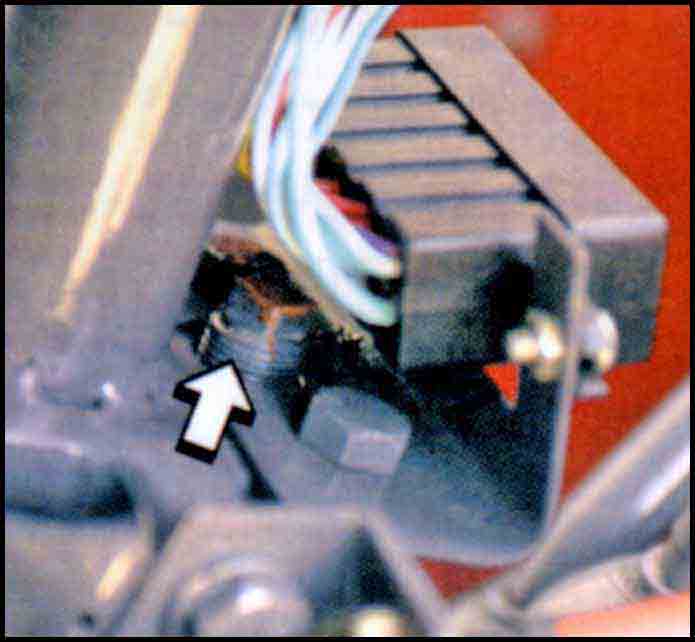

Starting Problems

Symptom: The tractor won’t start, or it’s hard to start.

Possible Causes: Battery issues, fuel supply problems, clogged air filters, or issues with the glow plugs (in diesel tractors).

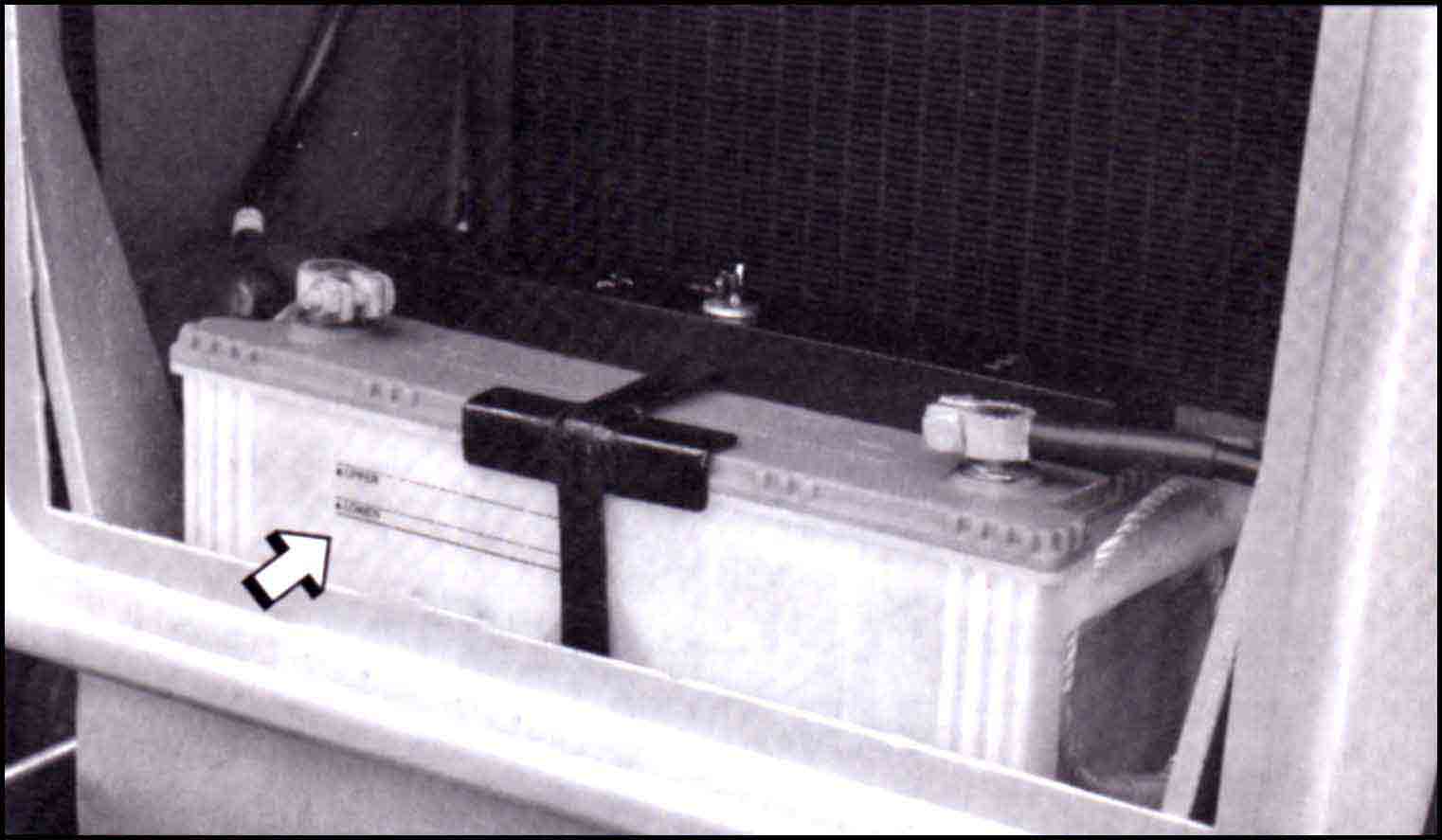

Fix: Ensure the battery is charged and the connections are clean and tight. Check the fuel level and quality (diesel can degrade over time). Replace or clean air filters regularly. For diesel engines, checking and replacing glow plugs might be necessary.

Overheating

Symptom: The tractor overheats during operation.

Possible Causes: Low coolant levels, a malfunctioning thermostat, or a clogged radiator.

Fix: Regularly check the coolant level and refill as necessary. Inspect the thermostat and radiator for any blockages or malfunctions and clean or replace them if needed.

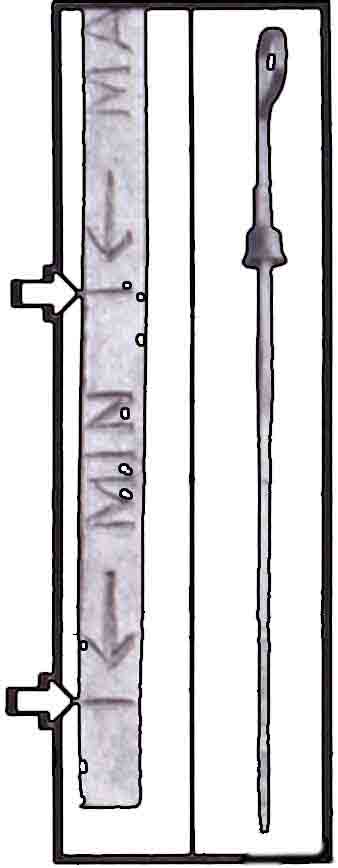

Power Loss

Symptom: The tractor loses power under load or has diminished performance.

Possible Causes: Dirty fuel filter, air intake issues, or transmission problems.

Fix: Replace the fuel filter and inspect the air filter and intake manifold for any blockages. For transmission issues, check the fluid level and quality—refer to a professional if complicated transmission repairs are required.

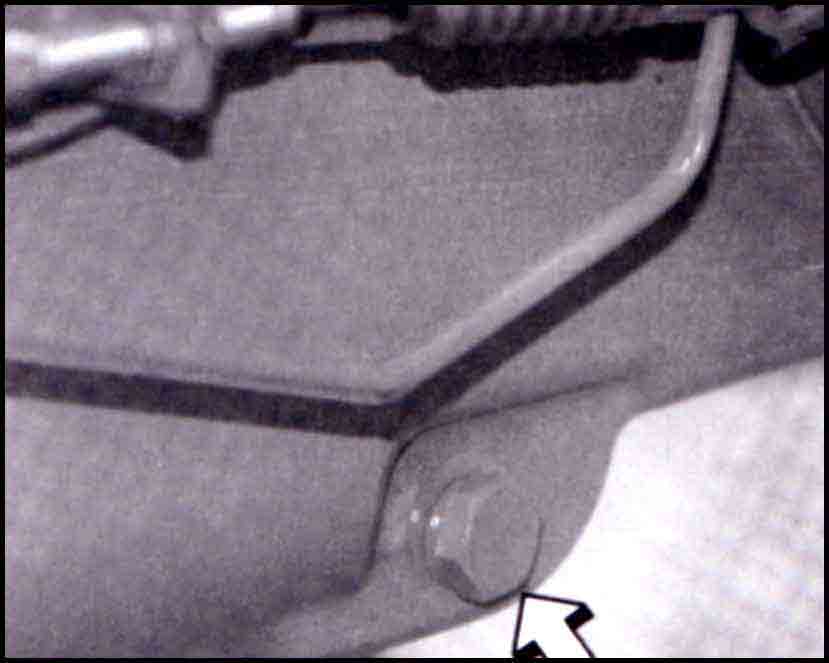

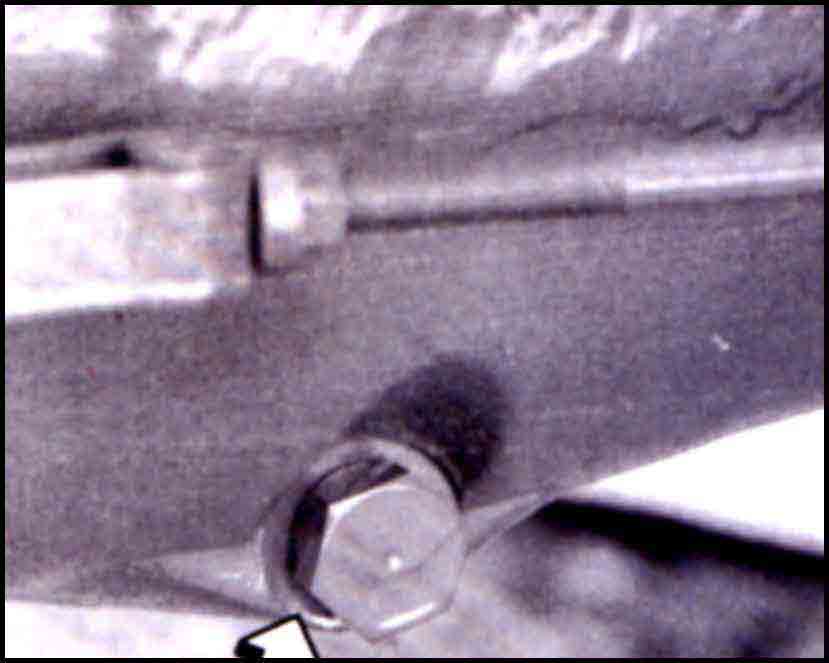

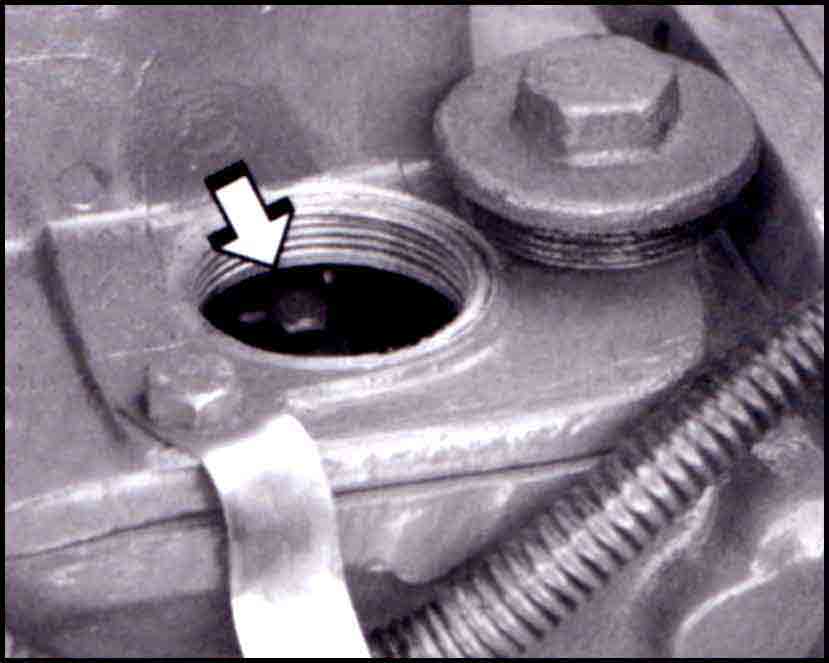

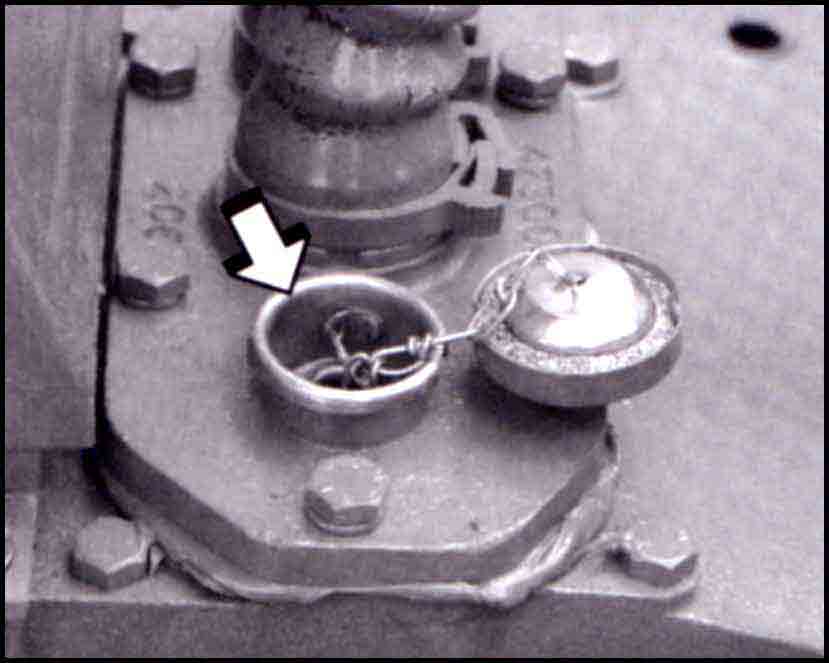

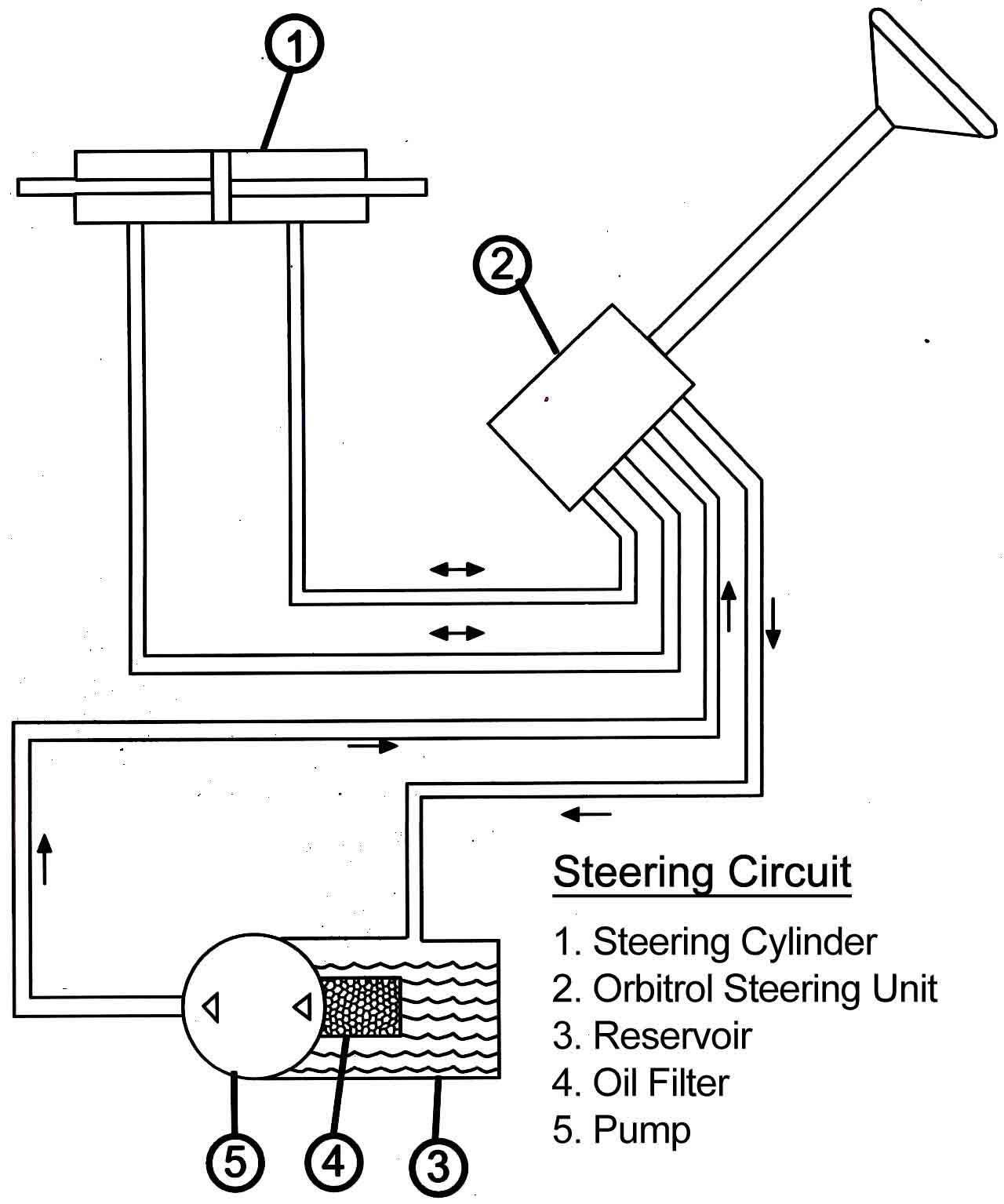

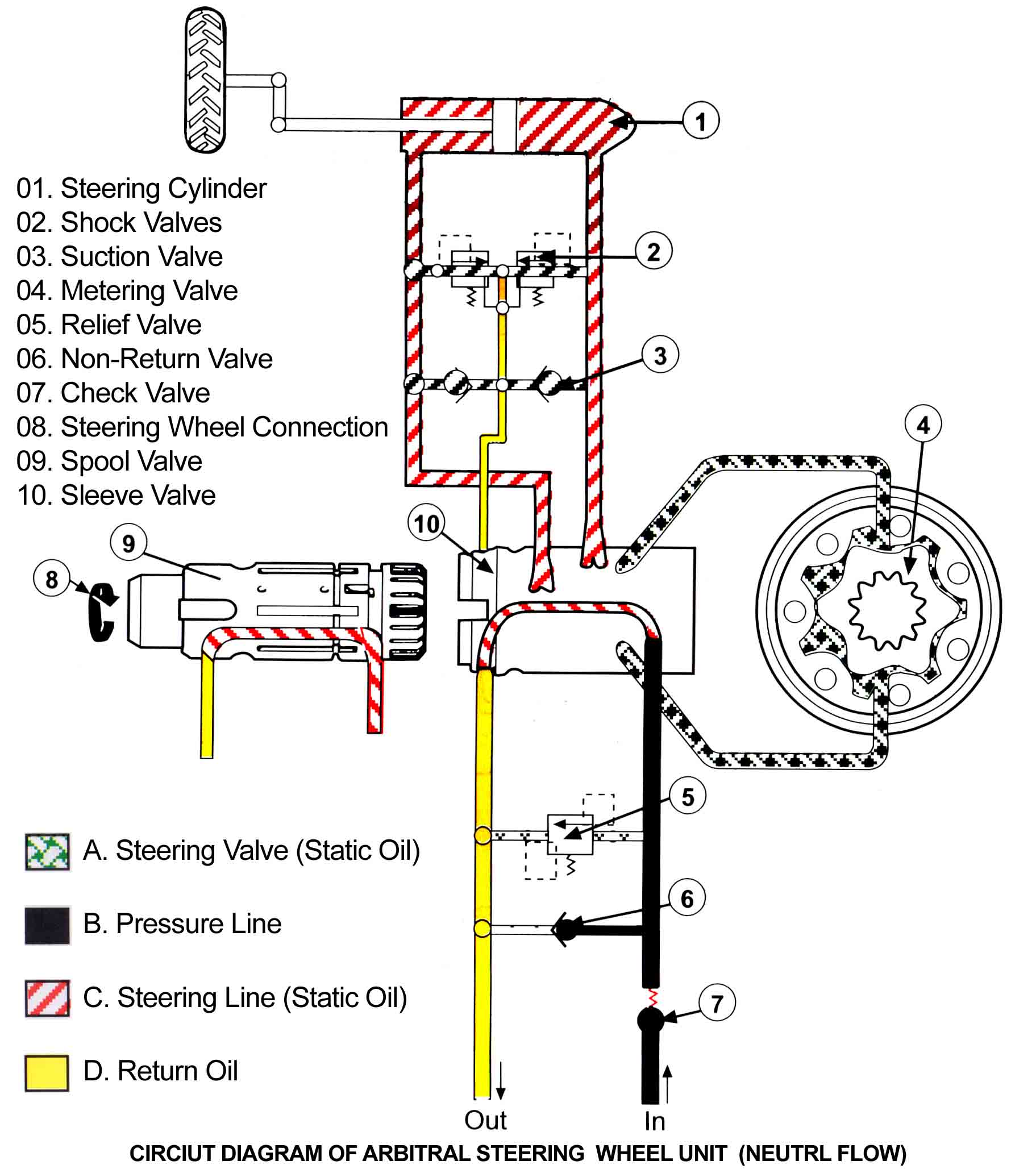

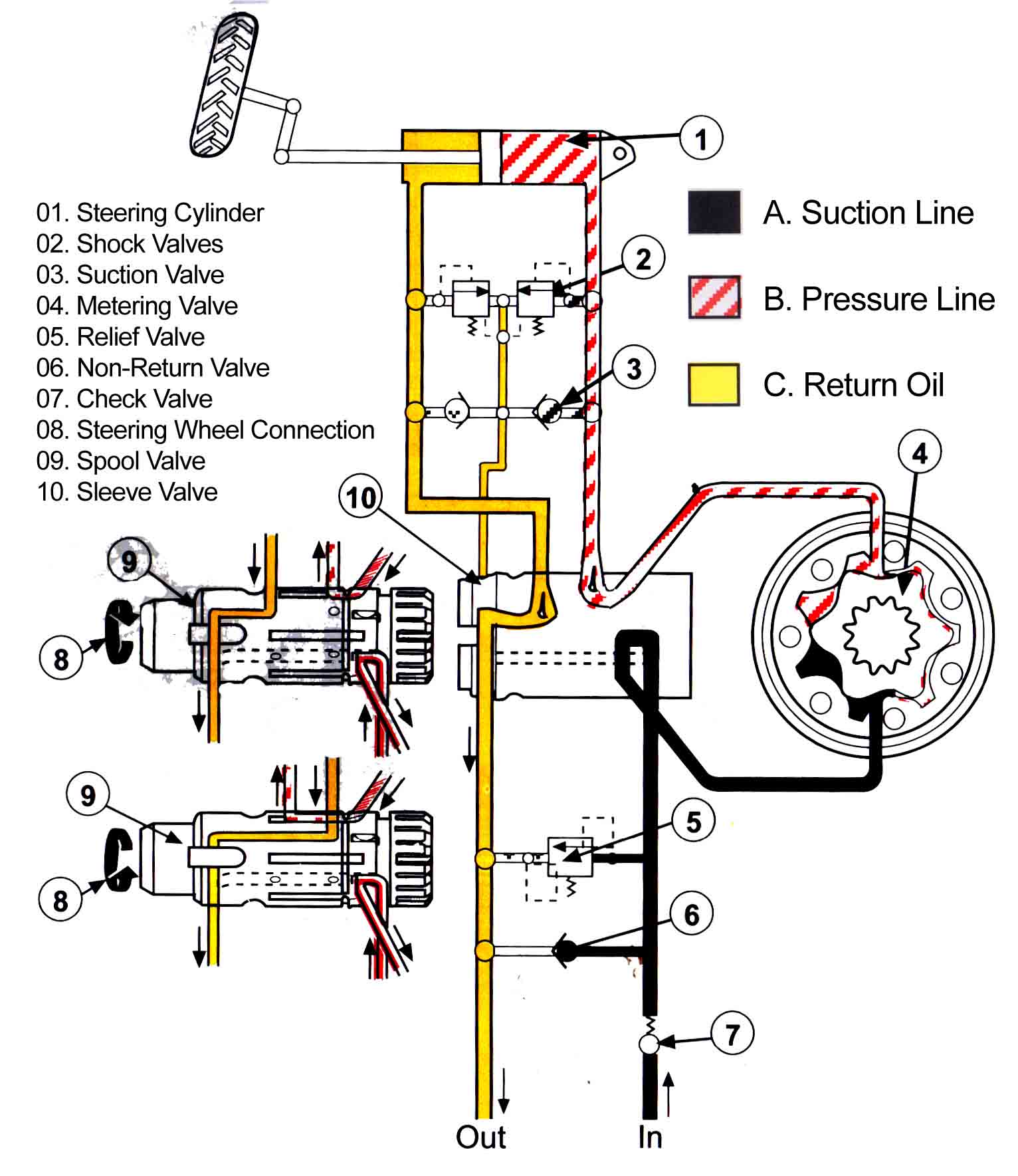

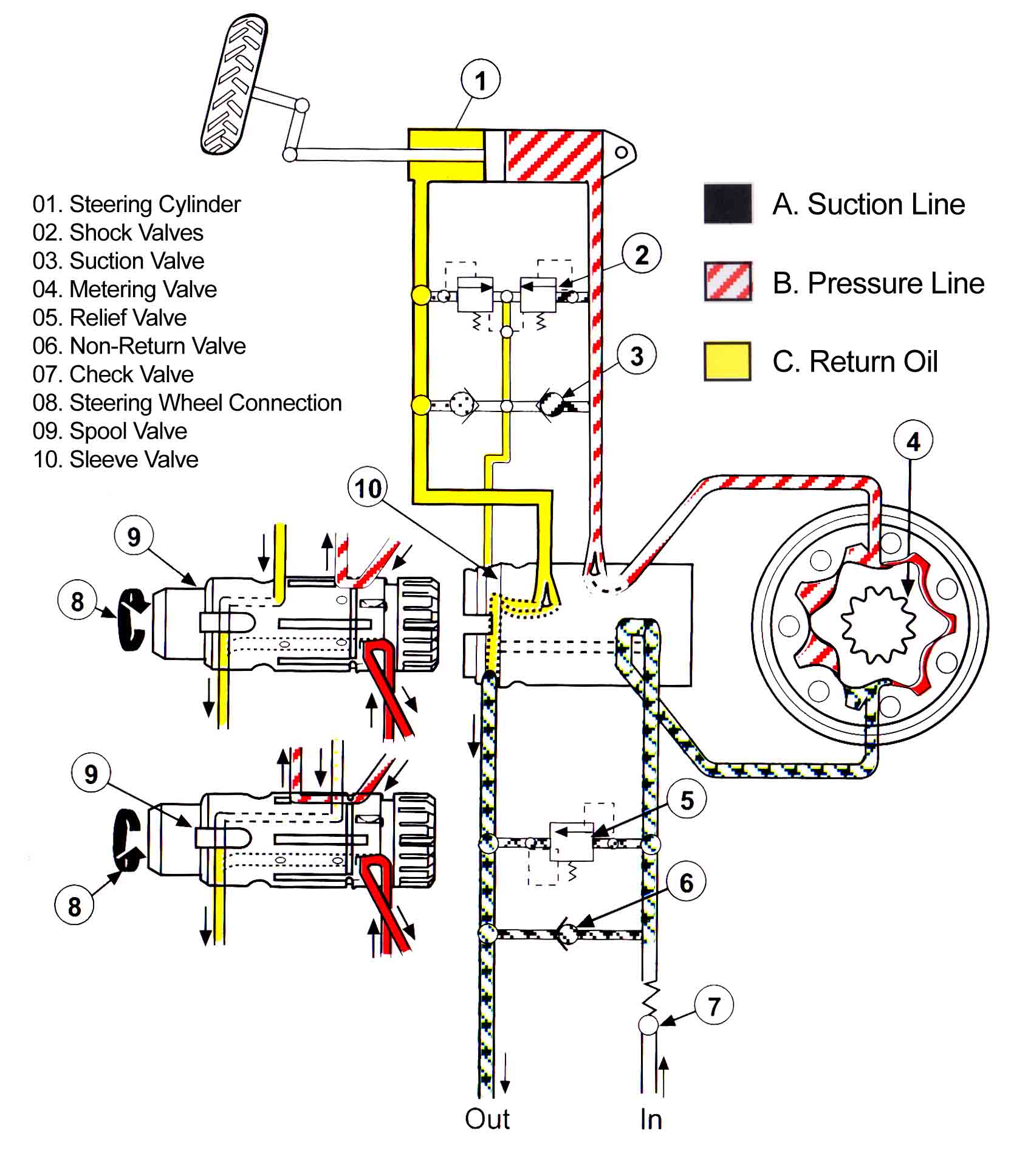

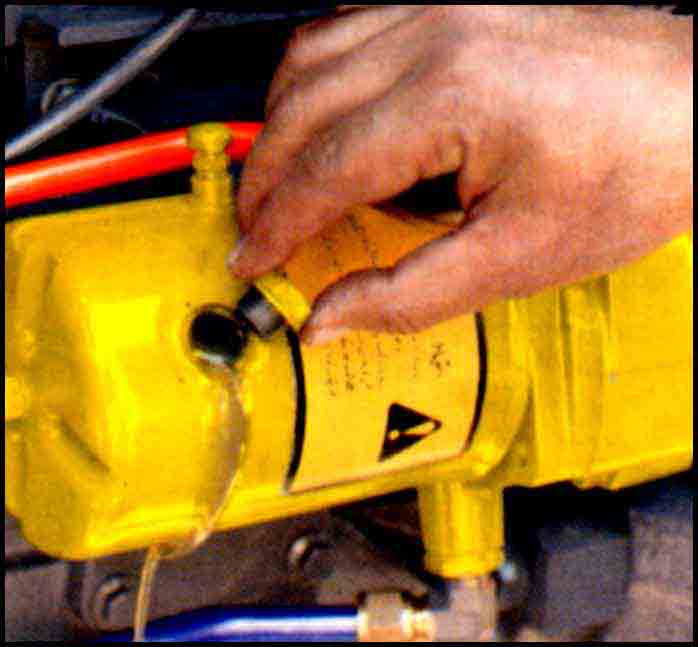

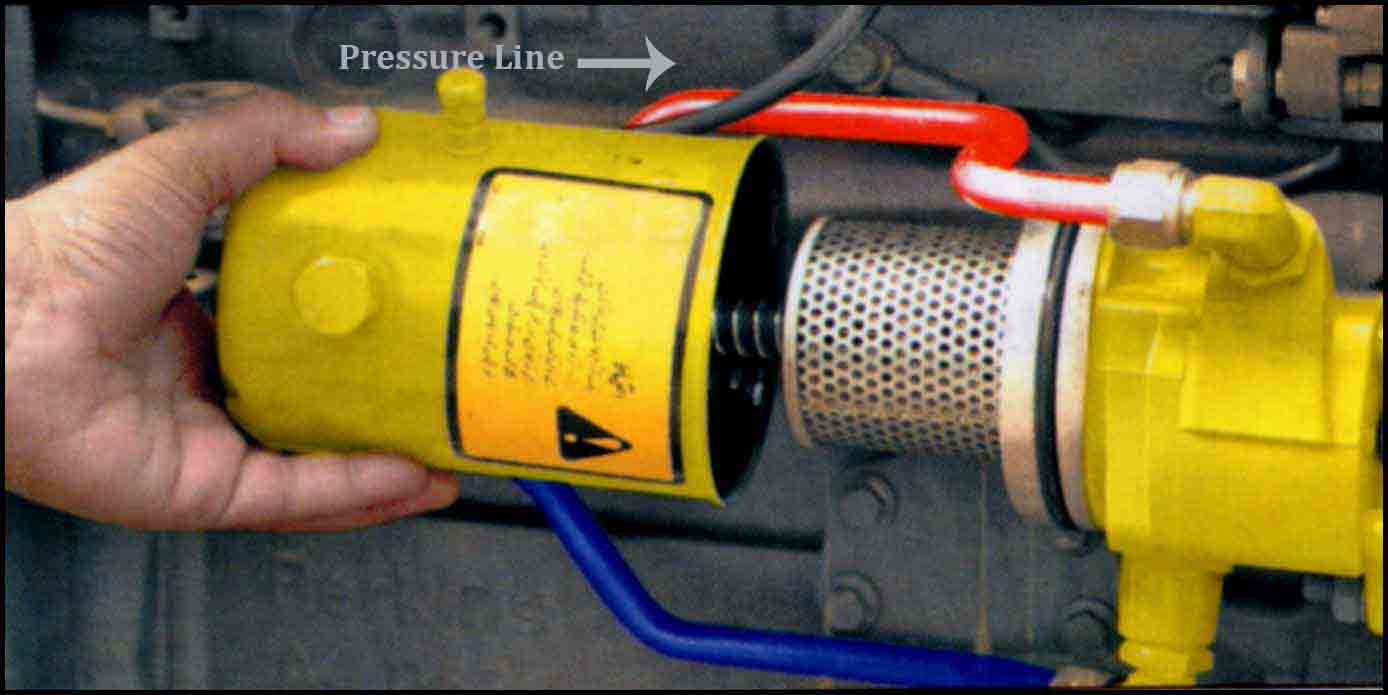

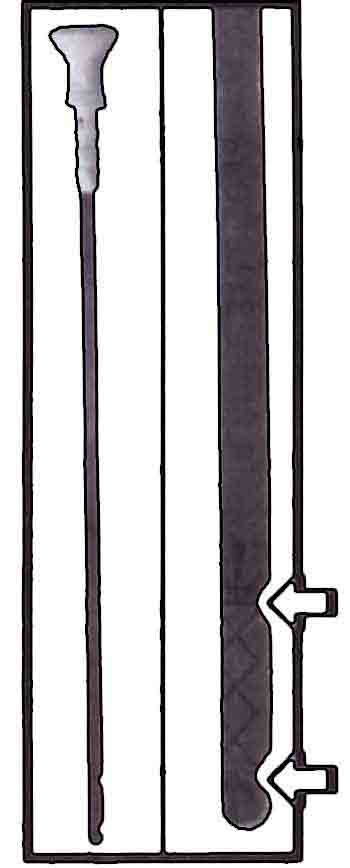

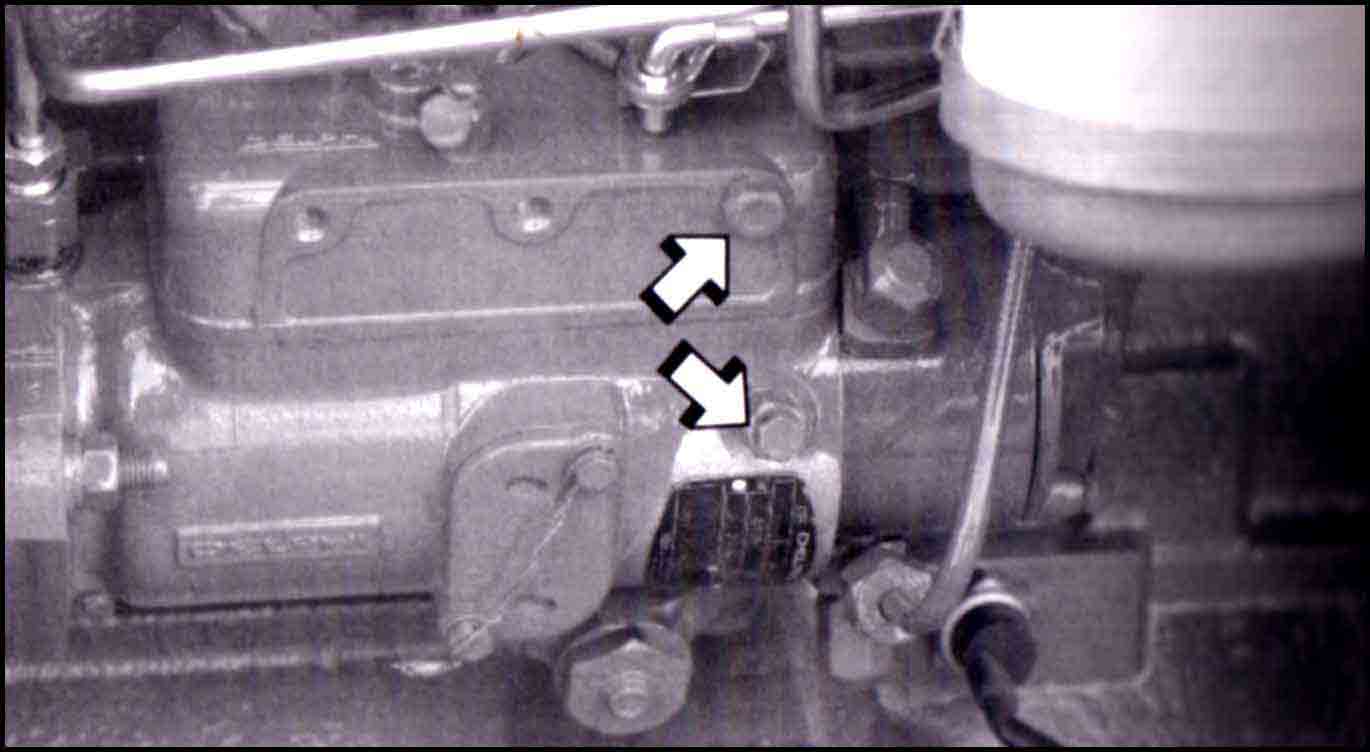

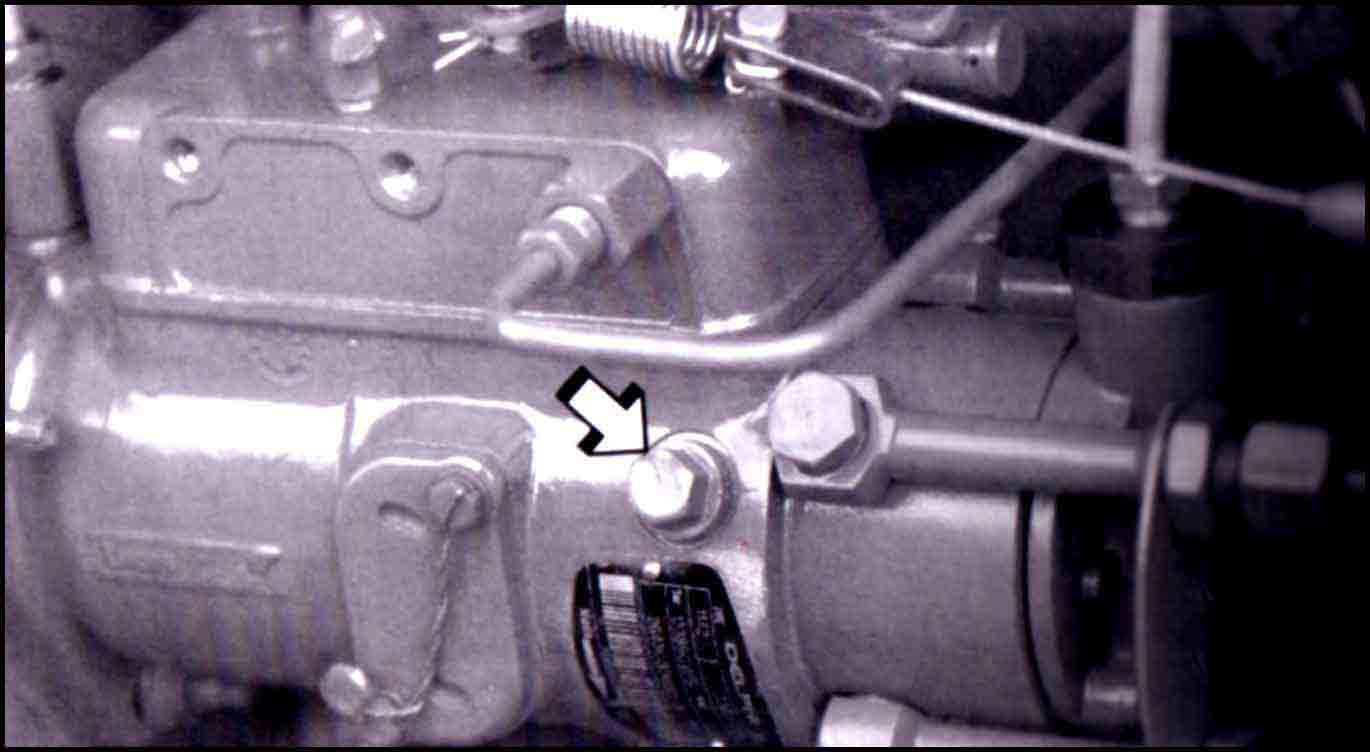

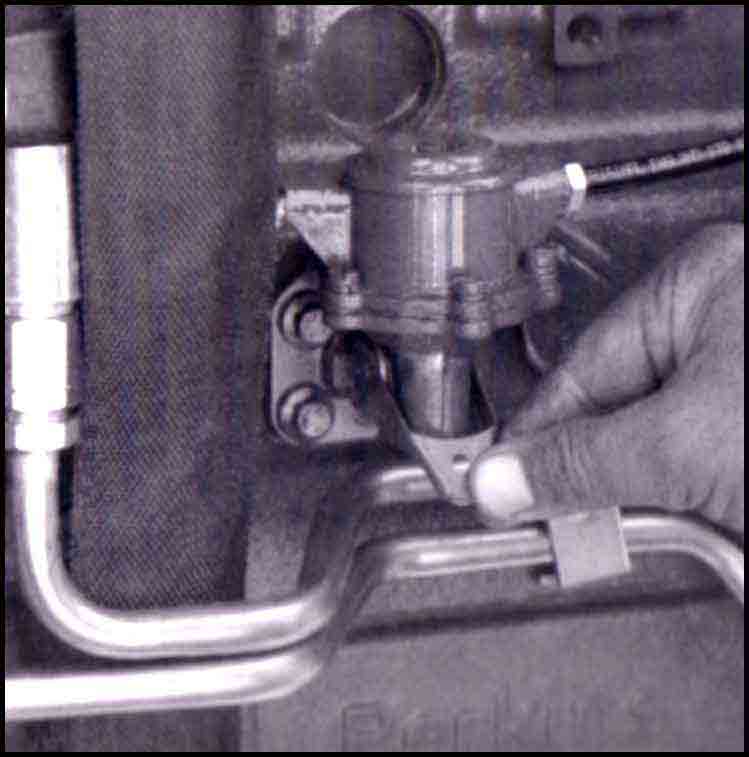

Hydraulic Issues

Symptom: Hydraulics are slow, weak, or non-responsive.

Possible Causes: Low hydraulic fluid, air in the system, or worn hydraulic pump.

Fix: Check the hydraulic fluid level and replenish if low. Bleed the system to remove air. Inspect the hydraulic pump and other components for wear and tear, replacing parts as necessary.

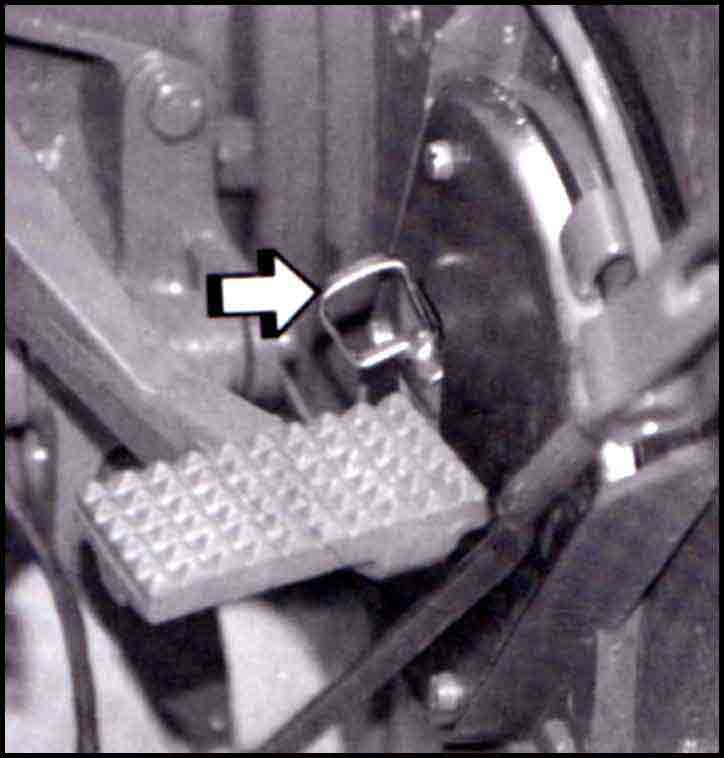

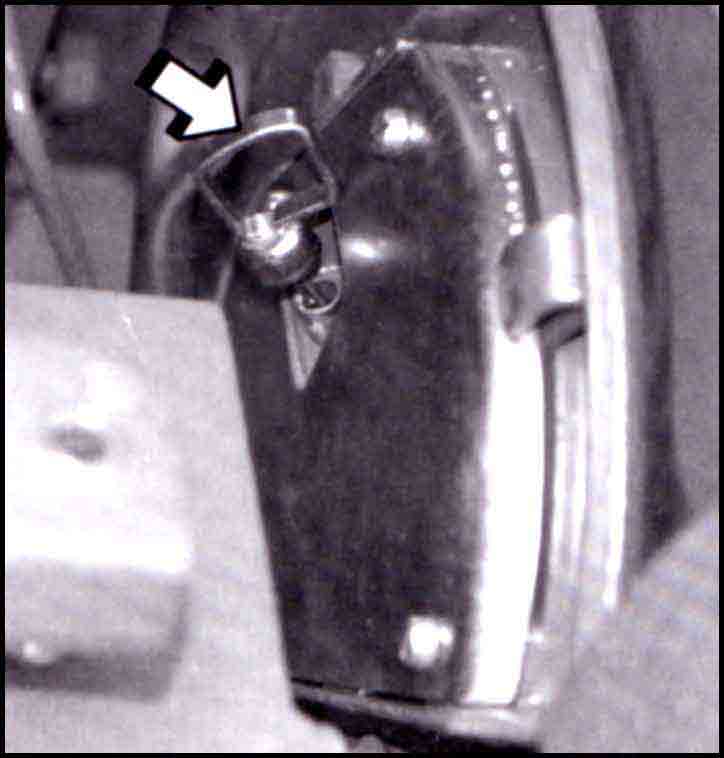

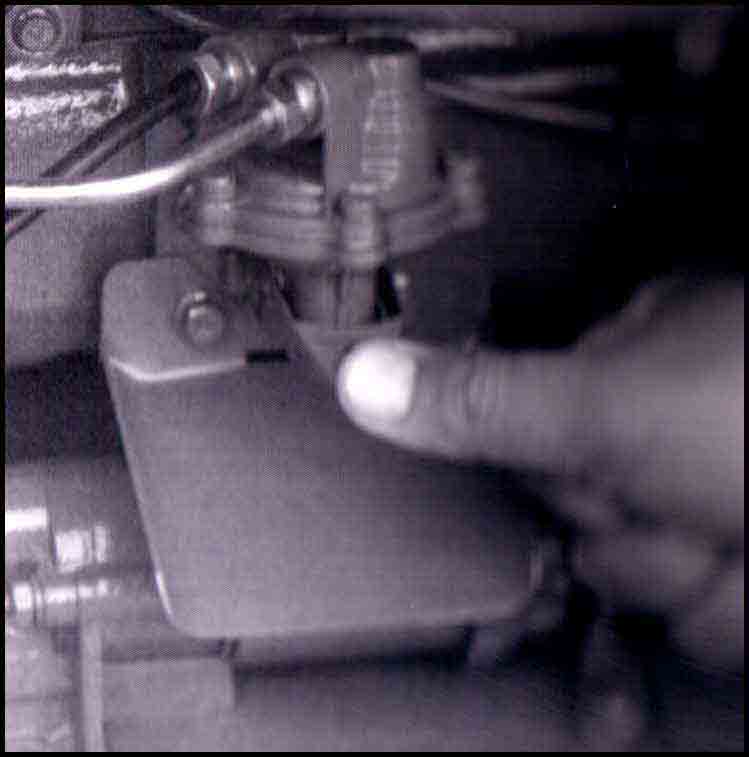

PTO (Power Take-Off) Problems

Symptom: The PTO doesn’t engage or lacks power.

Possible Causes: Faulty PTO clutch, low hydraulic fluid, or mechanical damage.

Fix: Inspect the PTO clutch for wear and adjust or replace it if needed. Ensure the hydraulic fluid is at the right level. Check for and repair any mechanical damages.

About Tractors PK

Tractors PK is proud to serve the agricultural community in Gambia and beyond. Our dedication to providing high-quality tractors and farm equipment is matched only by our commitment to excellent customer service. We understand the challenges faced by farmers and agriculture enthusiasts, which is why we offer an extensive range of products tailored to meet the unique needs of the Gambian agriculture sector.

Whether you’re in the market for a new tractor or seeking advice on maintaining your current machinery, Tractors PK is here to help. Visit our website or contact us directly to learn more about our offerings and how we can assist in enhancing your farming operations.

A tractor is an indispensable tool for any farm, but it’s not immune to problems. By understanding common issues and how to address them, you can ensure your tractor remains a reliable asset in your agricultural endeavors. Remember, regular maintenance is key to preventing many of these issues from arising in the first place. For those in Gambia looking for top-tier tractors and farm equipment, Tractors PK offers a comprehensive range designed to meet your farming needs. We’re here to support you in keeping your machinery in peak condition, so you can focus on what you do best—farming.