|

|

|

|

|

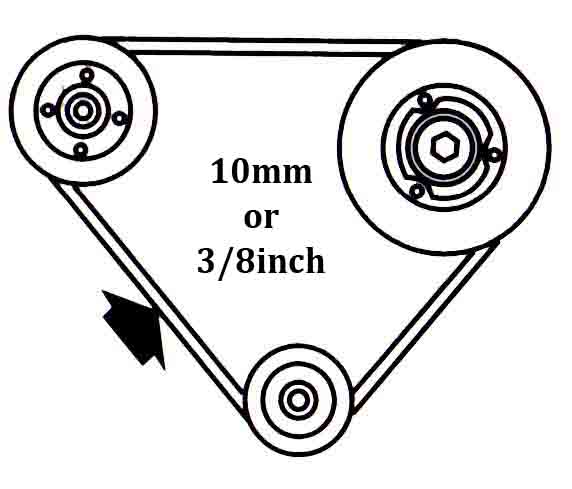

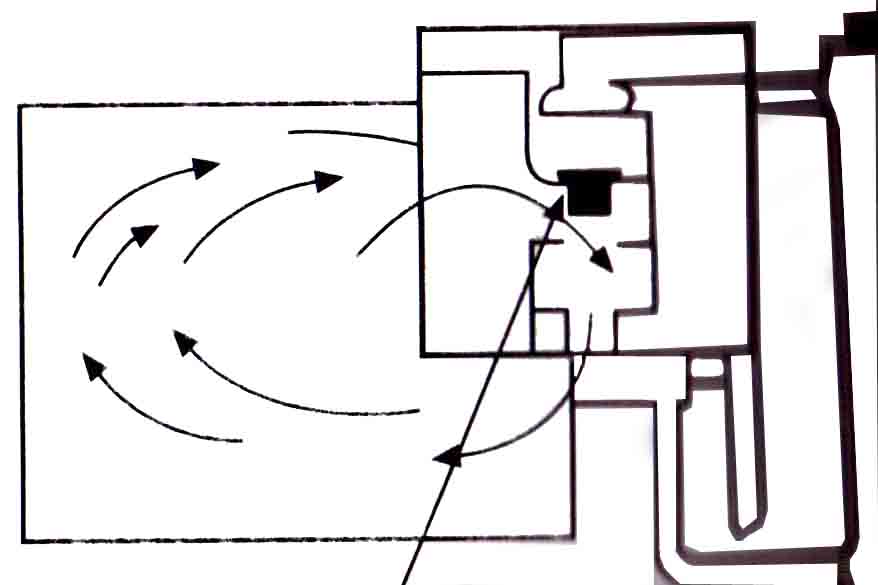

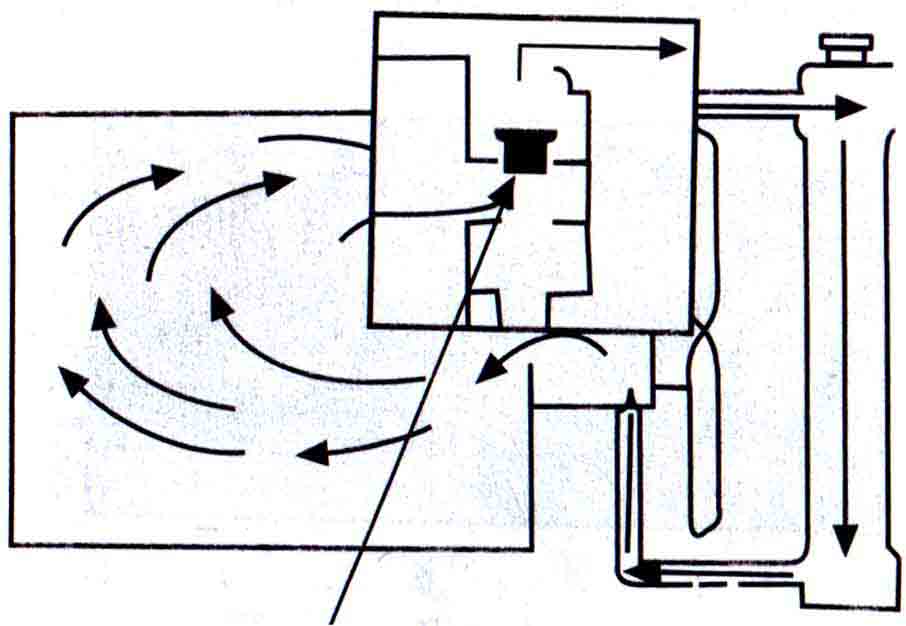

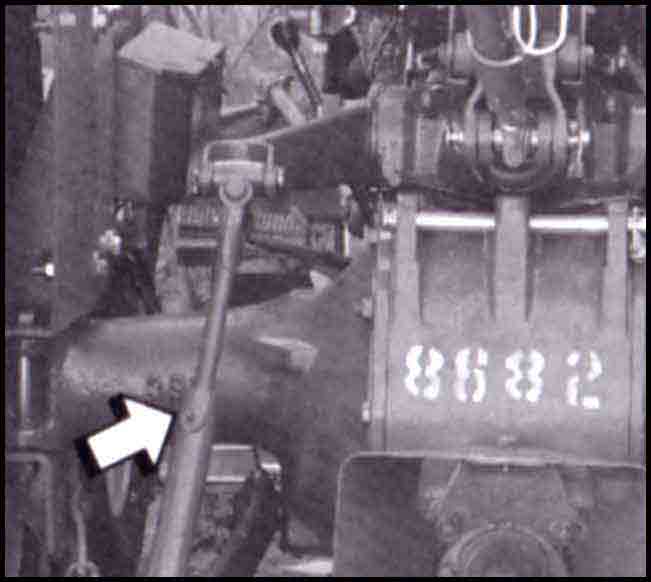

MF-240/350/260

|

MF-375/385

|

|

||

|

|

|

|

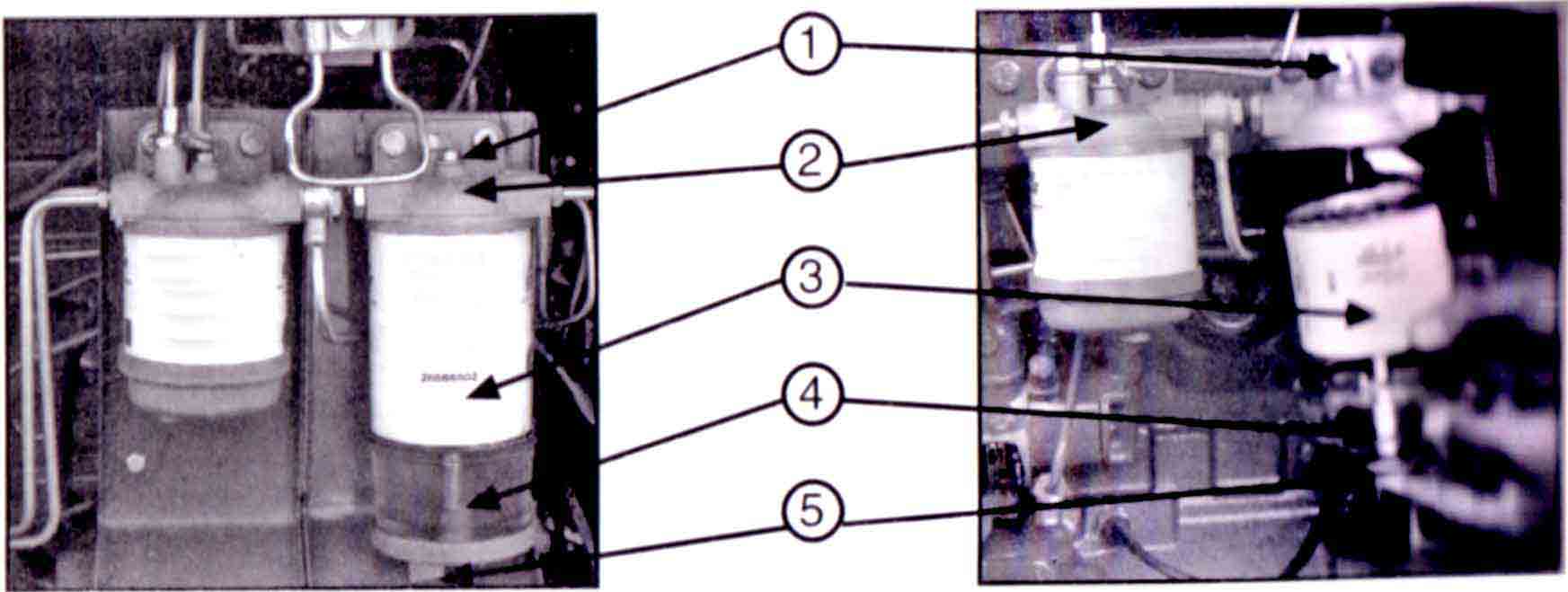

Oil Filter MF-240/350

|

Oil Filter MF-260

|

Oil Filter MF-375/385/3854WD

|

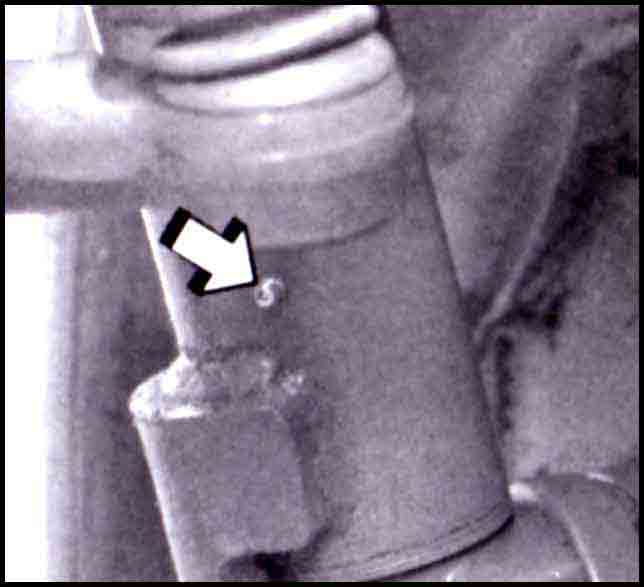

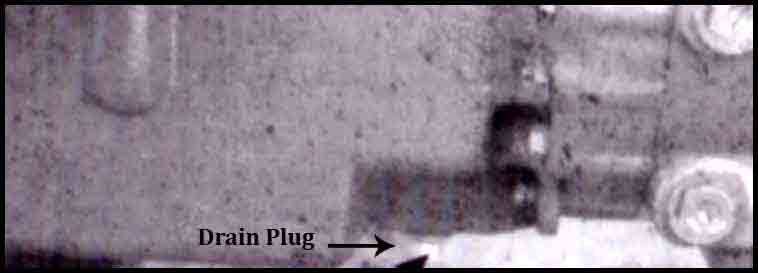

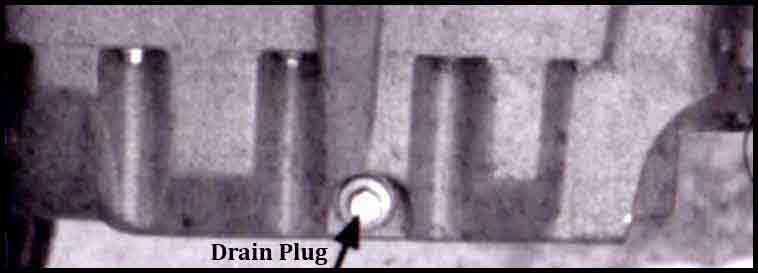

| Slowly fill fresh oil through the oil-inlet until it starts to come out of the oil drain plug hole. Immediately re-plug the drain tightly. | ||

|

|

|

|

Oil Filter MF-240/350

|

Oil Filter MF-260

|

Oil Filter MF-375/385/385 4WD

|

|

||

|

|

|

|

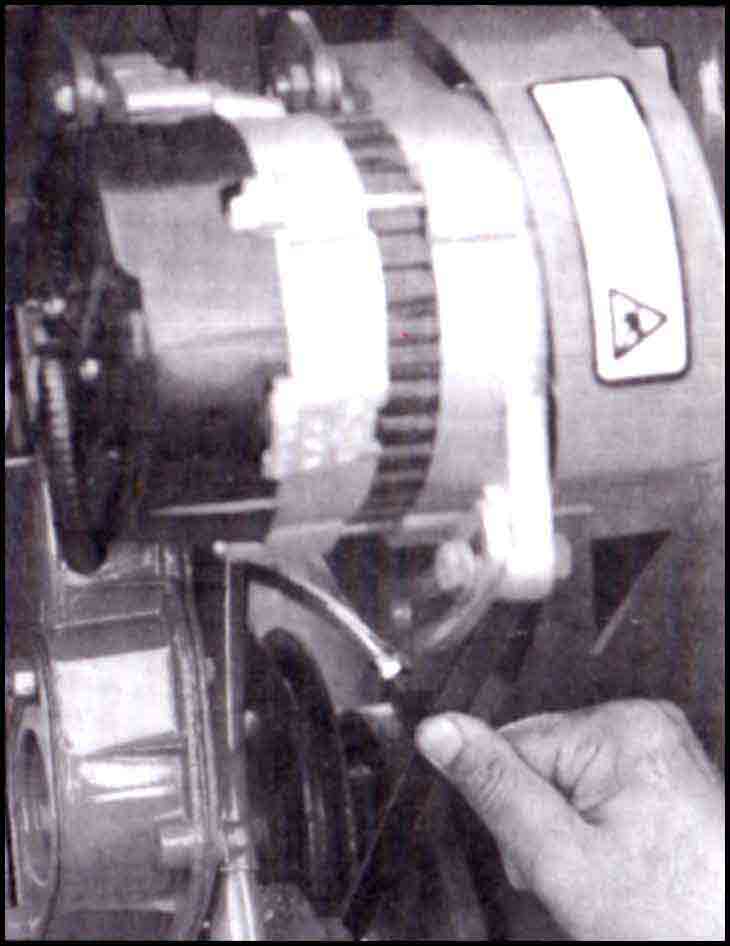

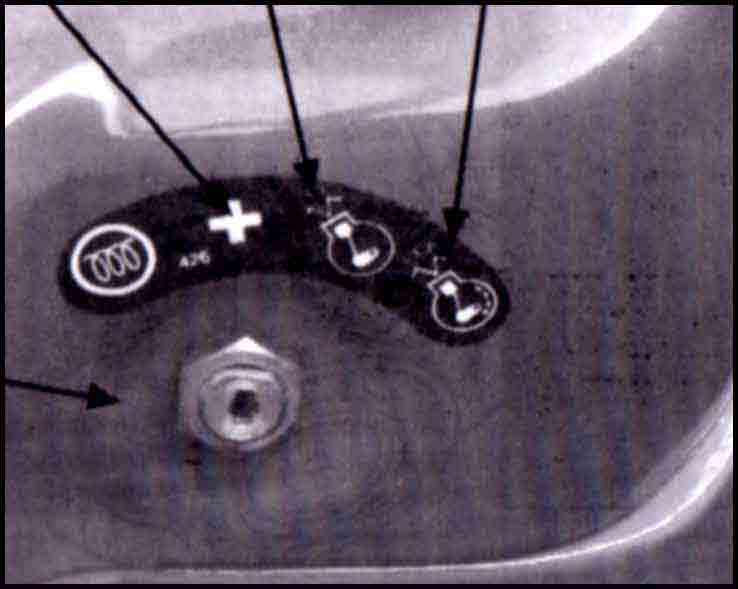

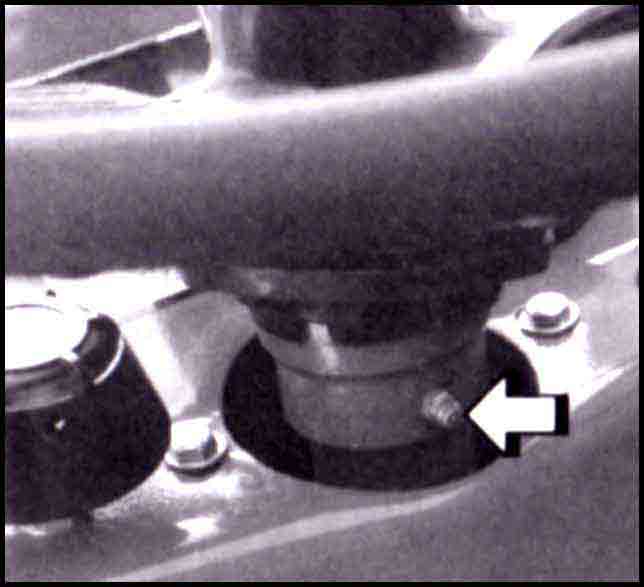

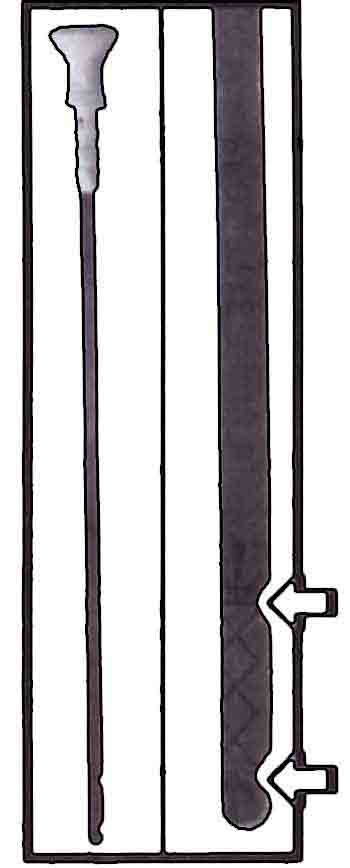

Location of checking the engine oil MF-240/350

|

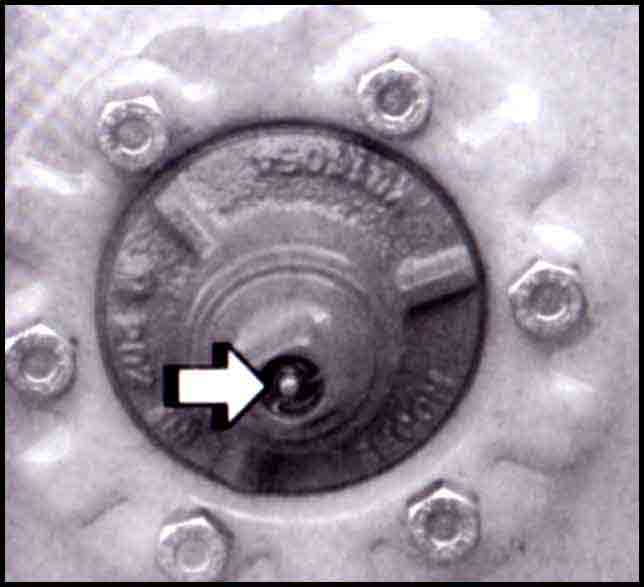

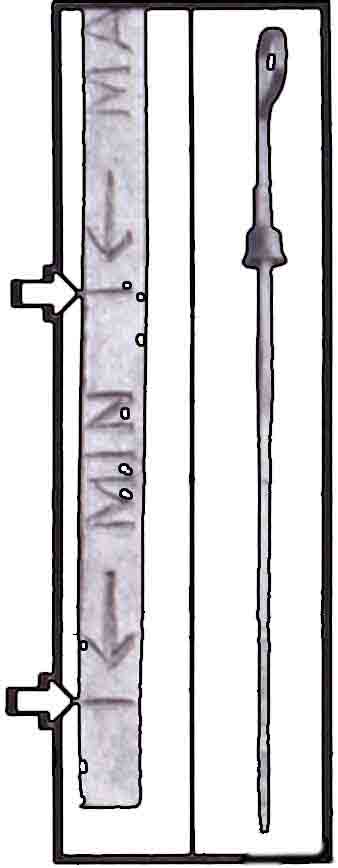

MF-240/350/260 (MIN, MAX)

|

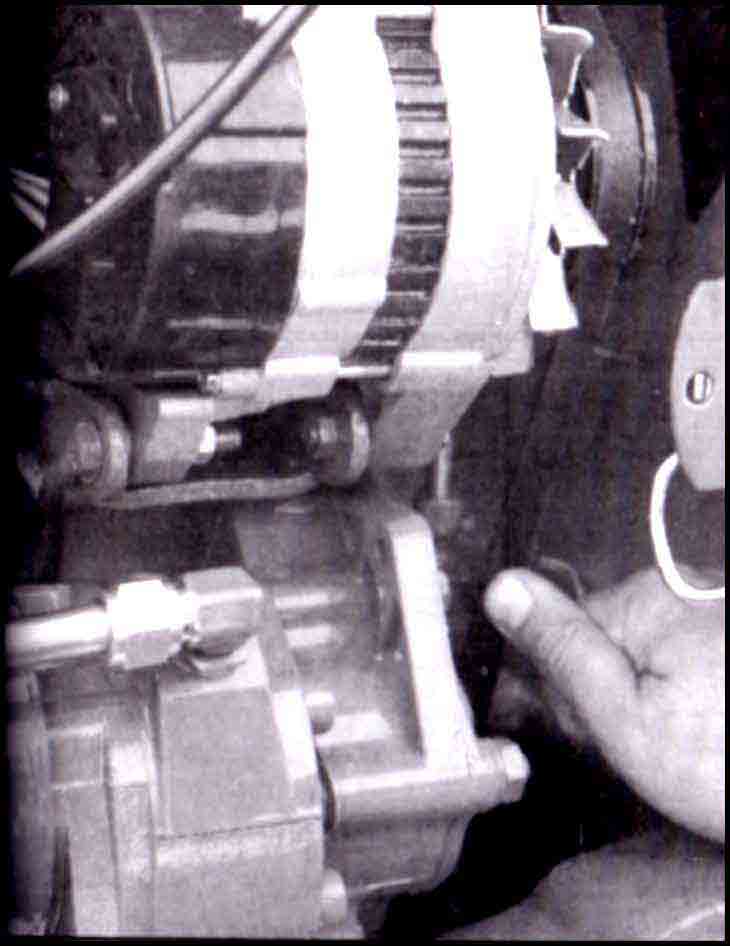

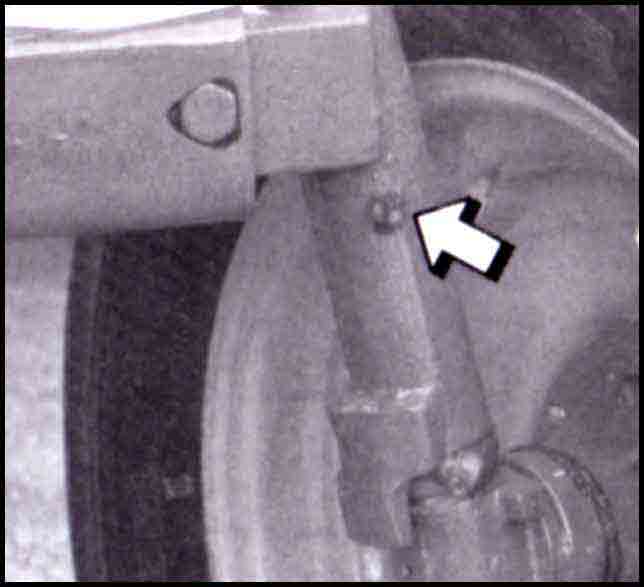

MF-375/385 (MIN, MAX)

|

|

||