What engine is in a Massey Ferguson 360?

It provides a

It provides a

It provides a

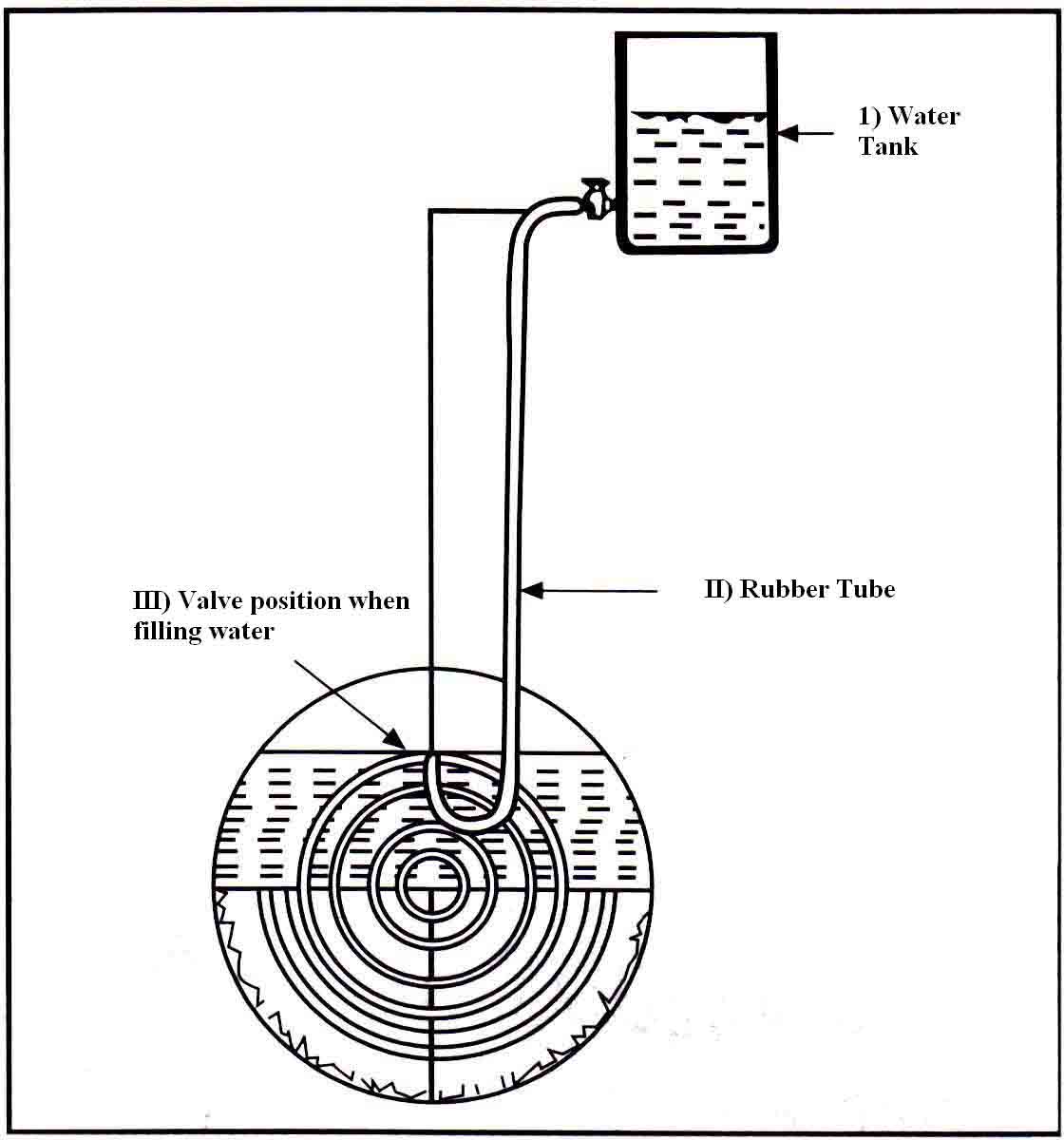

It provides a| The probability of tires to slip increases when the tractor is light and is operating on hard ground. It reduces the performance, which cause increases diesel consumption. Experiments show that proper tire grip on the surface, tractor performance increases by 10 to 25 percent. To increase the surface grip in the rear tires, filling water in the tires is recommended. Below is the method to fill water in the tires with a simple instrument.

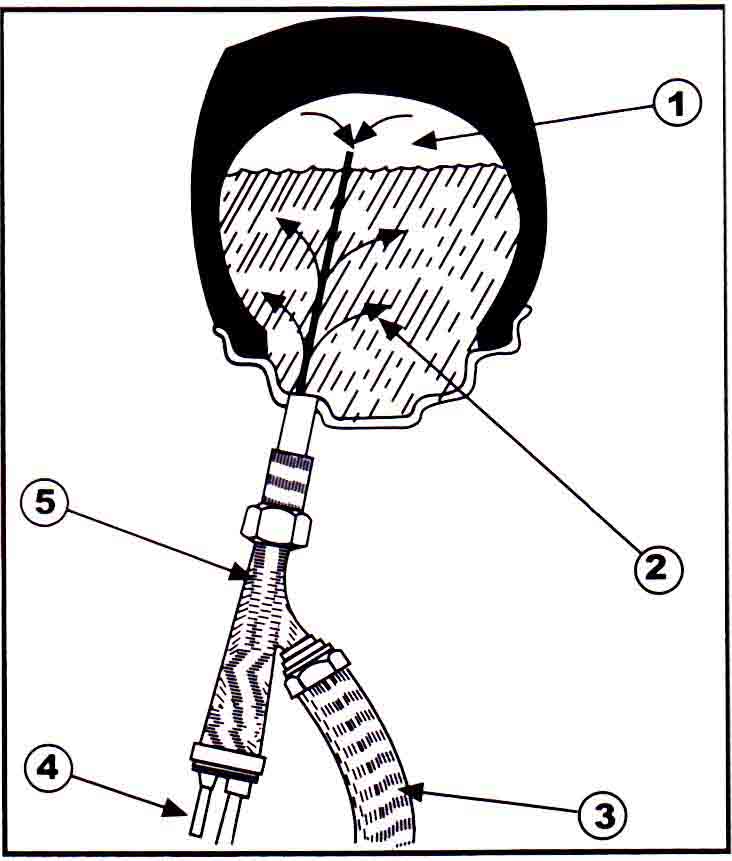

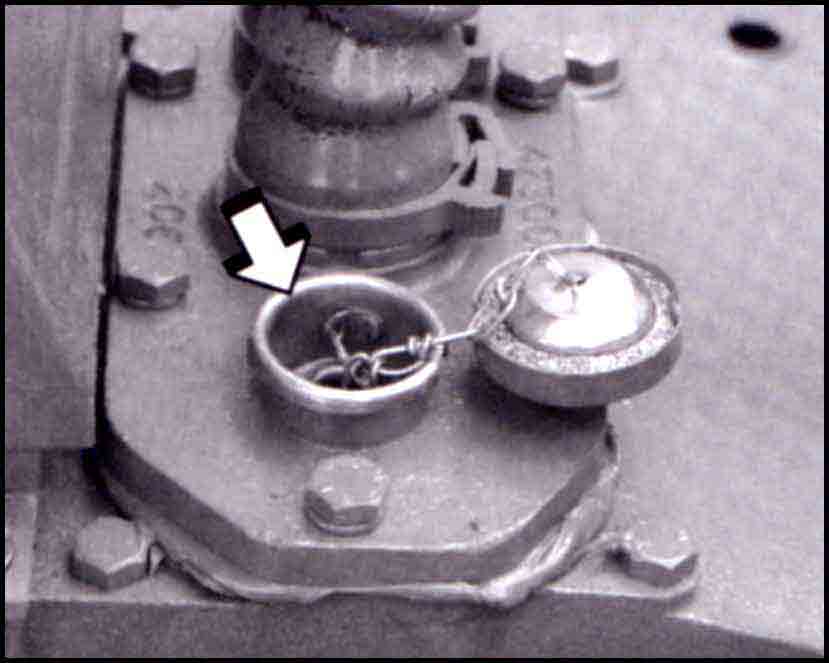

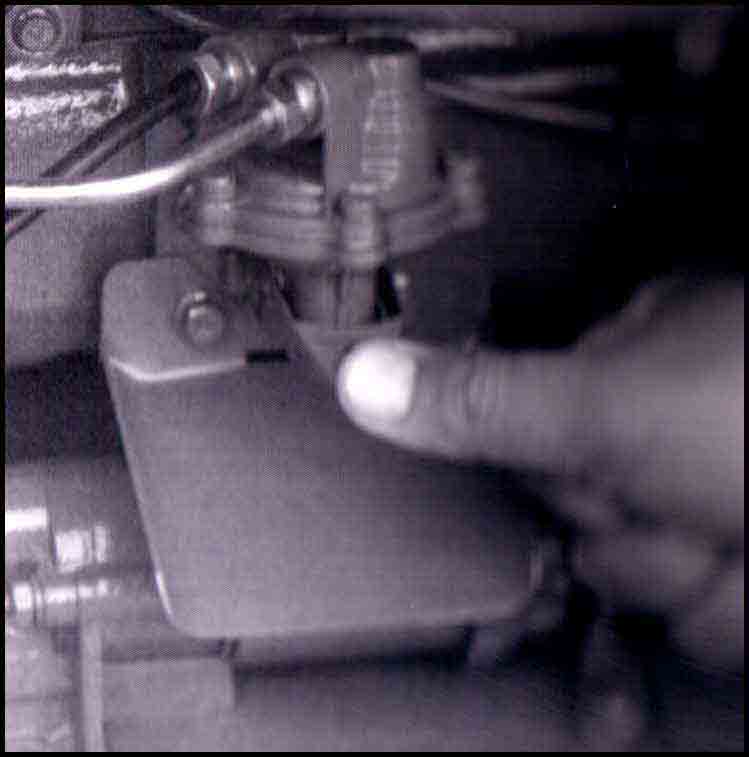

Water Can Be Filled In the Tyre Using the Instrument

|

|

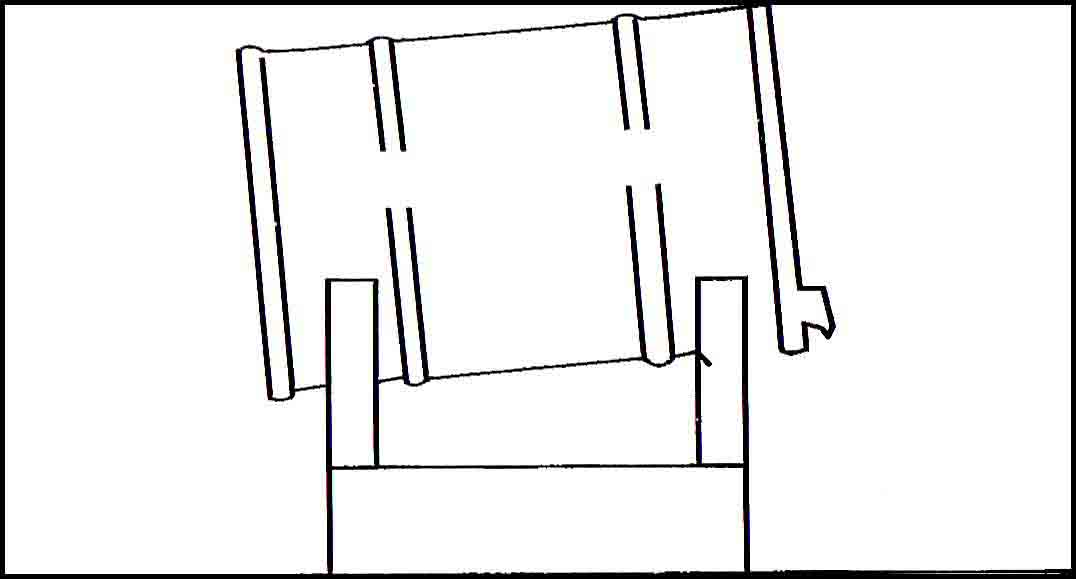

| 1. Air 2. Pressurized entry of water in the tube 3. Pipe to fill water 4. Deflation pipe 5. Instrument shell | |

|

|

Precautions

|

|

In order to get proper performance out of the tractor, the proper air pressure in the tires is very important because engine power is wasted when the air pressure is low or high, and required productivity is not obtained, either. It is important for every tractor owner to have an air gauge and a manual air pump handy. Improper air pressure can cause the following harm:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Use the instructions below to maintain proper air pressure in Massey Ferguson tractors

VERY IMPORTANT If there is additional load on the front part of the tractor, as the front-end loader or front blade is used, inflate the front tires to 40 psi. Using oil or grease to clean the tires reduces their life. Water is sufficient to clean these. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tractors PK is one of the top suppliers and exporters of Massey Ferguson Tractors and their compatible farm implements from Pakistan to across the globe including tractor models like MF-240 (50hp), MF-260 (60hp), MF-360 Turbo (60hp), MF-375 (75hp), MF-385 2WD and 4WD (85hp) at the lowest price. Usually, farming tractors used to pull a variety of farm implements to increase the farming process as well as the agriculture business.

We serve customers in Africa & the Caribbean region especially in Botswana, Ghana, Kenya, Nigeria, Uganda, Zambia, Zimbabwe, Tanzania, DR Congo, South Africa, Algeria, Sudan, Morocco, Angola, Ethiopia, Egypt,, Mozambique, Madagascar, Cameroon, Côte d’Ivoire, Niger, Burkina Faso, Mali, Malawi, Senegal, Chad, Somalia, Guinea, Rwanda, Benin, Burundi, Tunisia, South Sudan, Togo, Sierra Leone, Libya, Congo, Liberia, Central African Republic, Mauritania, Eritrea, Namibia, Gambia, Gabon, Lesotho, Guinea-Bissau, Equatorial Guinea, Mauritius, Eswatini, Djibouti, Comoros, Cabo Verde, Sao Tome & Principe, Seychelles, Barbados, Belize, Iraq, Saudi Arabia, Lebanon, Oman, Kuwait, Qatar, Cayman Islands, Dominican Republic, Guyana, Haiti, Jamaica, Antigua and Barbuda, Dominica, Grenada, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Sint Maarten, Suriname, Trinidad and Tobago, Turks, and Caicos, etc.

7A Queen’s Road, Lahore, Pakistan.

Phone: +92-320-2390-002 / +92-321-2390-002

Email: [email protected]

Website: https://www.tractorspakistan.com

Social Links: https://www.facebook.com/TractorsPakistan

https://www.instagram.com/tractors.pk/

https://www.linkedin.com/company/tractorspk/

https://twitter.com/Tractorspk

https://www.youtube.com/user/Tractorspk

https://www.pinterest.com/Tractorsfrompakistan/

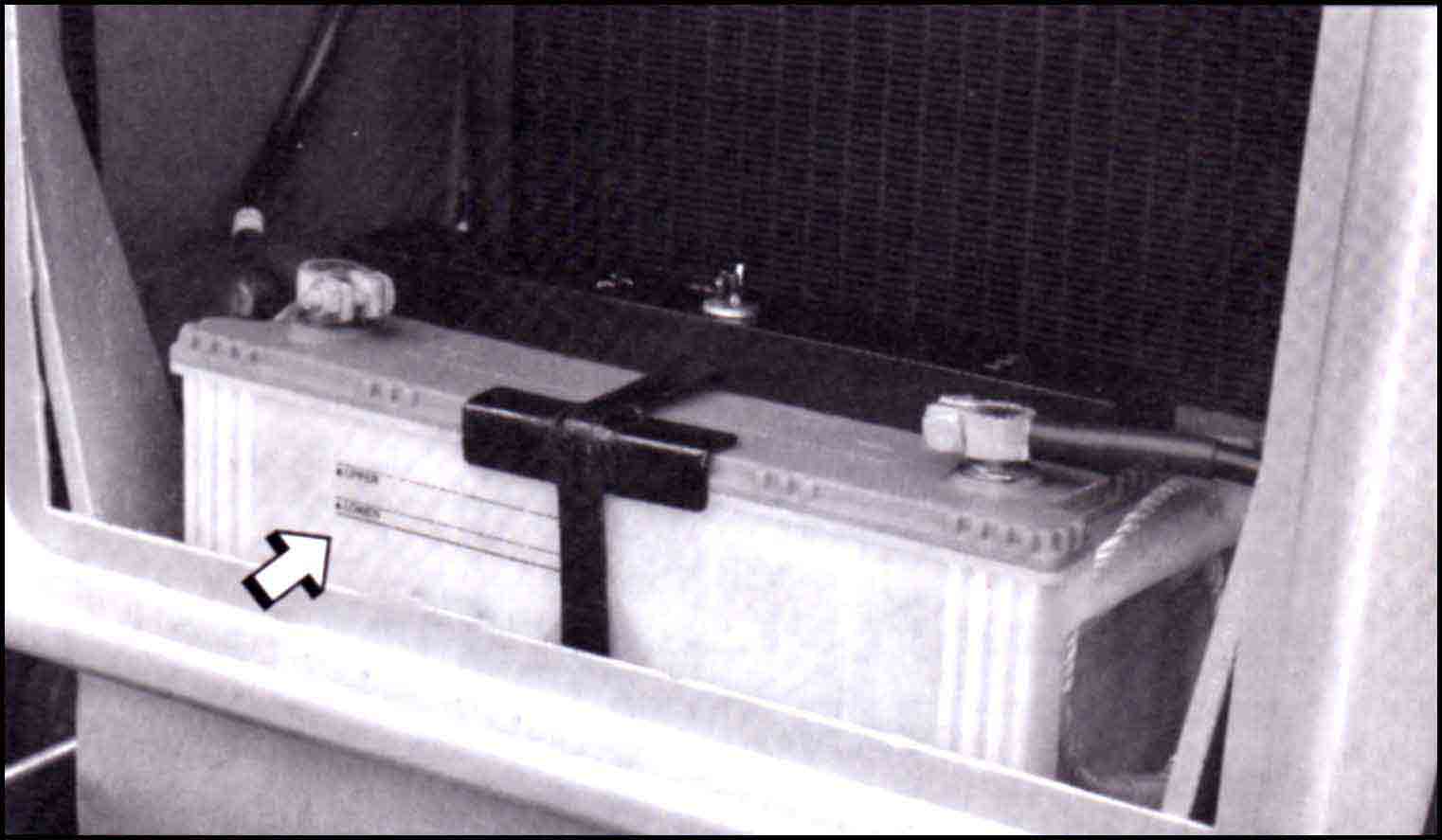

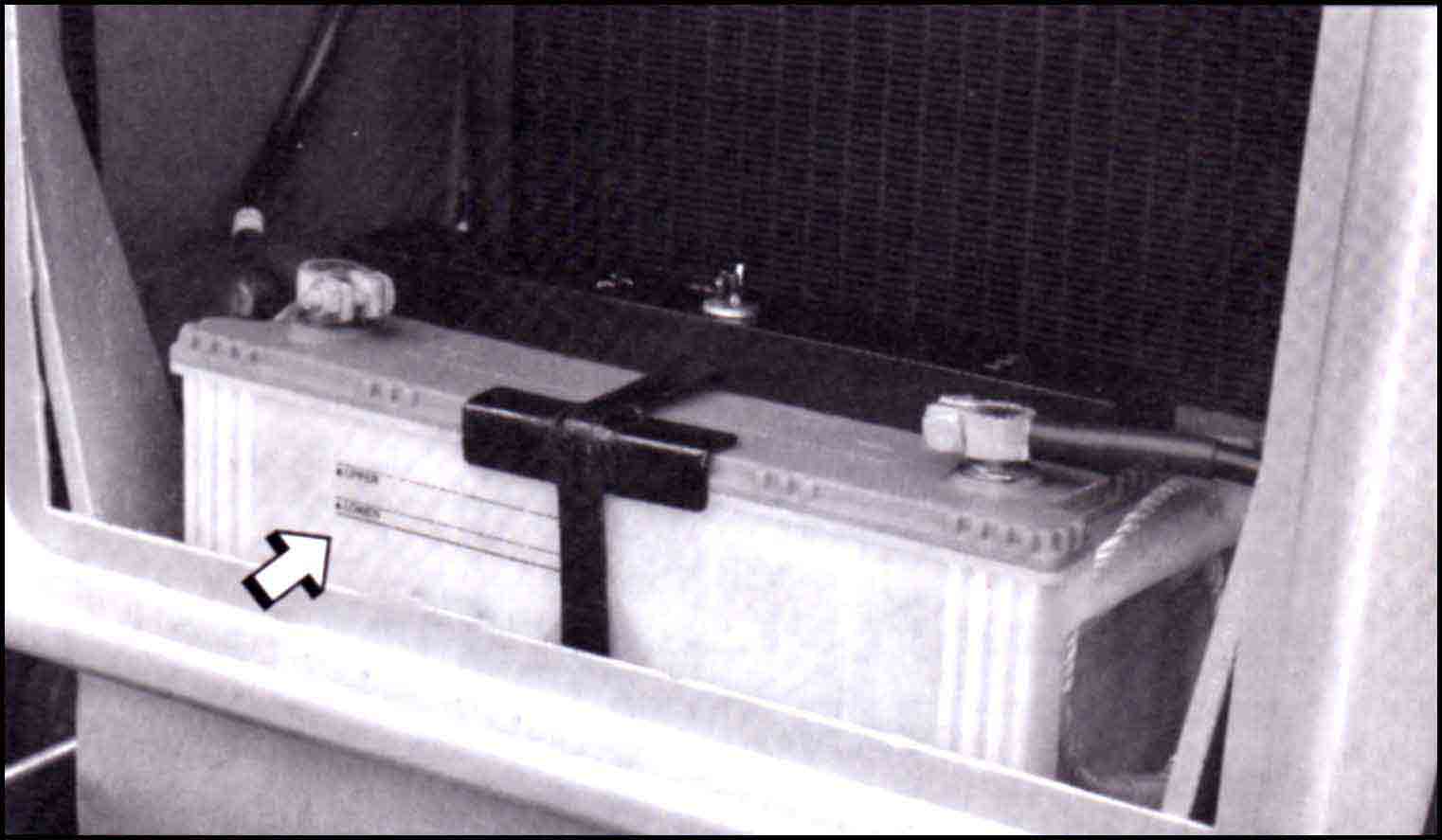

Maximum benefit can be obtained from the battery by following the instructions described below.

Often farmers leave the engine running during meal breaks when the battery is weak, which wastes a lot of diesel. The tractor battery should always be well charged, because high power is required to start the engine. If the battery does not have the required power, the engine starts with difficulty, which also wastes diesel. |

|

|

|

|

Battery MF-240/260/375 (water level)

|

Battery MF-385/385 4wd (inlets to pour distilled water)

|

MF-350/260

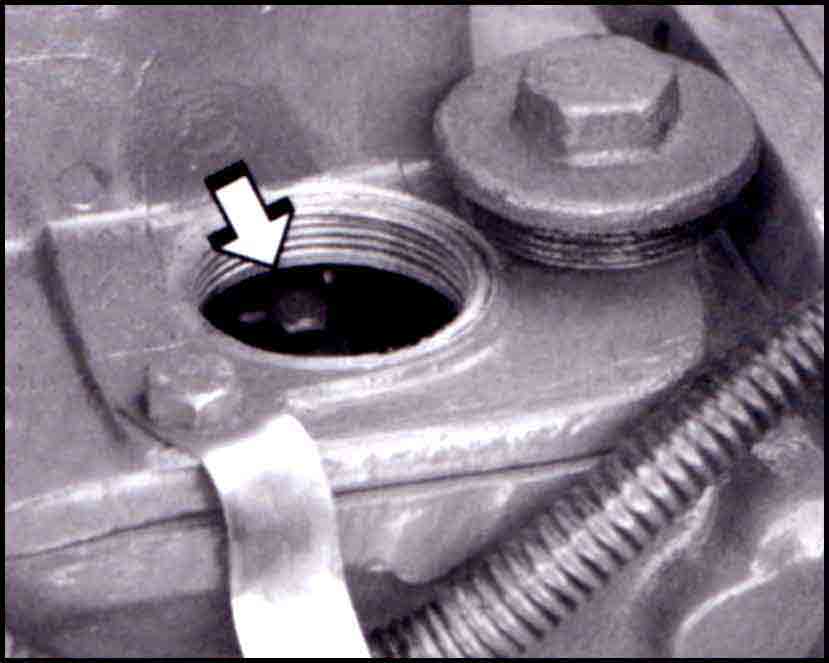

Mechanical steering has been installed in this tractor, in which to check oil in the steering box, remove the plug located on the steering box. Make sure the oil is completely filled with oil. Replenish if the oil level is low and tighten the plug back on.

Place to check / refill oil in the

steering assembly

MF-385/375/385 4WD

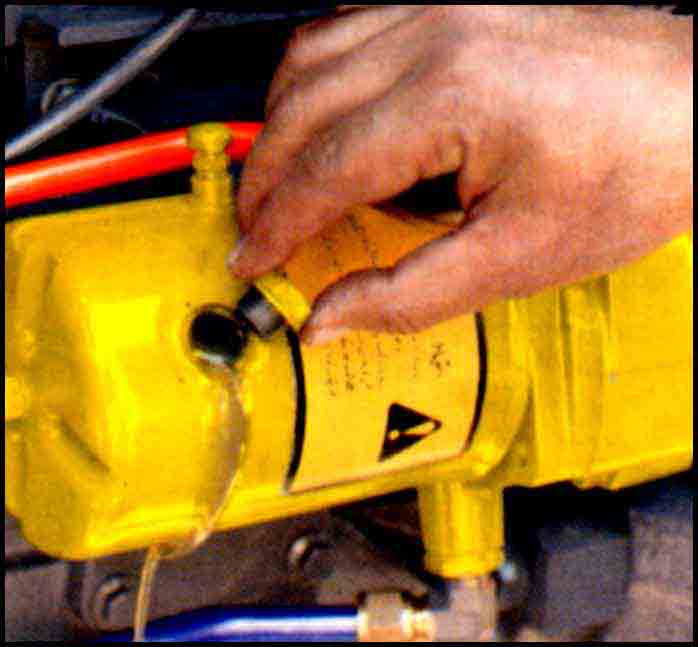

Power steering has been installed in this tractor. To check the oil in this unit, remove the oil reservoir plug located next to the steering pump at front of the engine. If the oil trickles slowly out of the hole, place the plug back in and tighten. Replenish if the oil level is low.

Place to check / refill oil in the steering

pump MF 375/385/385 4WD

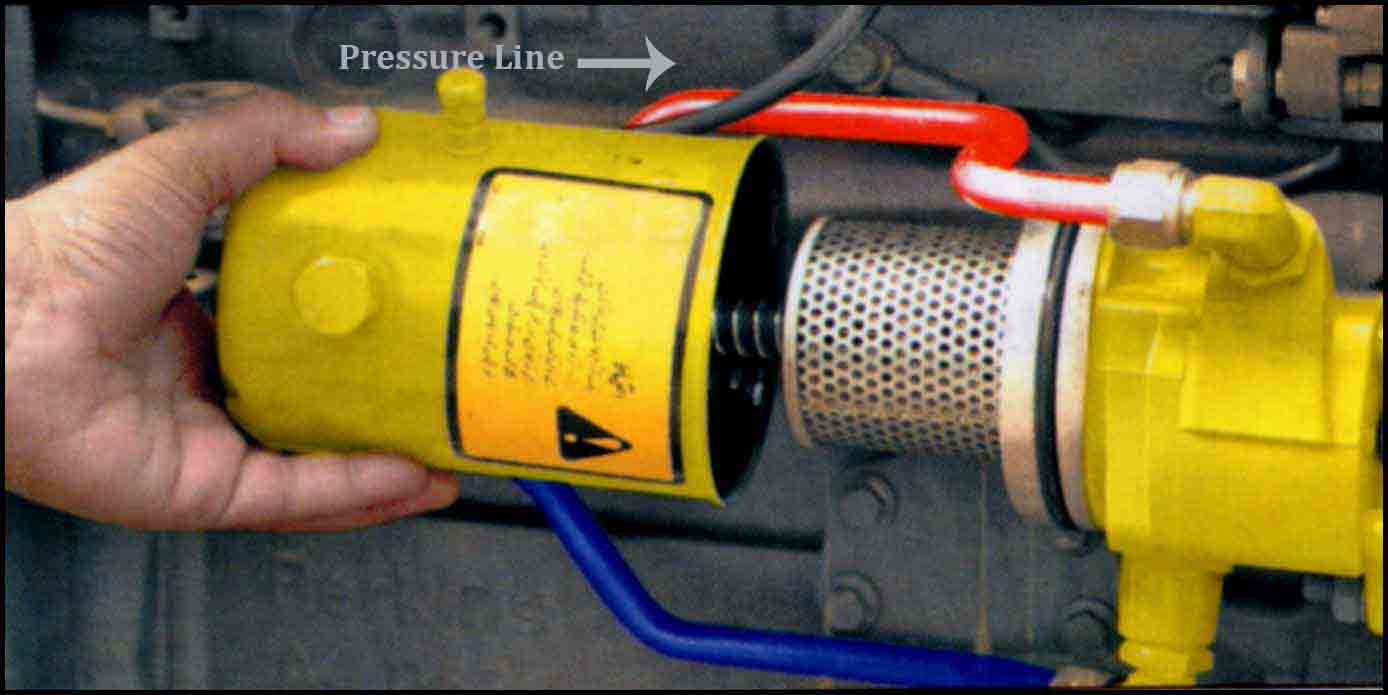

| How to Remove Power Steering Oil

Remove the bolts located behind the steering box, remove the filter etc and drain the oil. How to Replenish Oil Remove the plug on the reservoir. Start the engine. Straighten the front wheels and then turn the steering clockwise one complete circle. Turn off the engine and replenish oil. Oil Capacity The steering pump reservoir in MF385/385 4WD can hold up to 2 liters of oil. Change the power steering oil with the filter after every 250 hours. |

|

|

How to change power steering filter MF-385/385 4WD

|

|

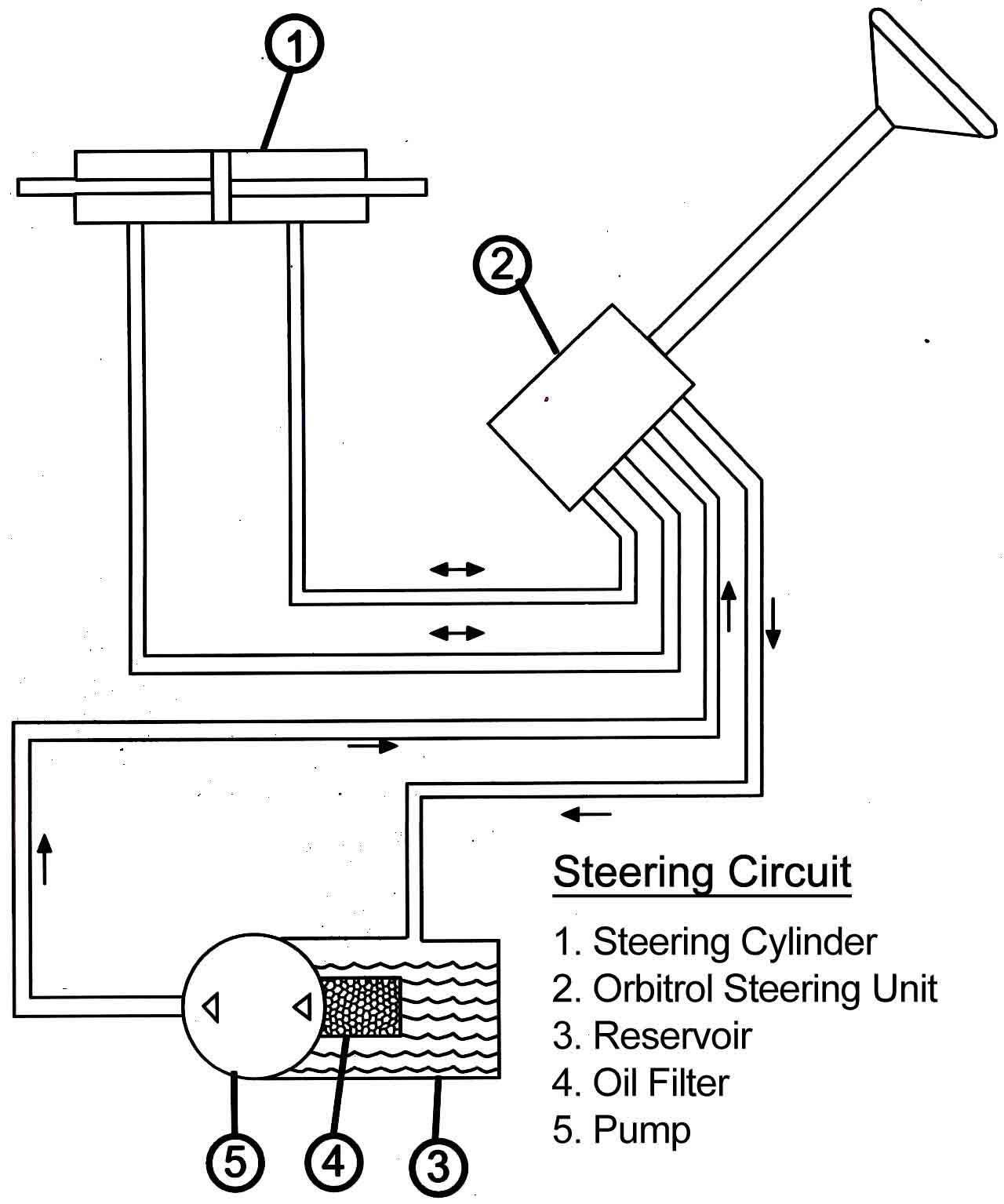

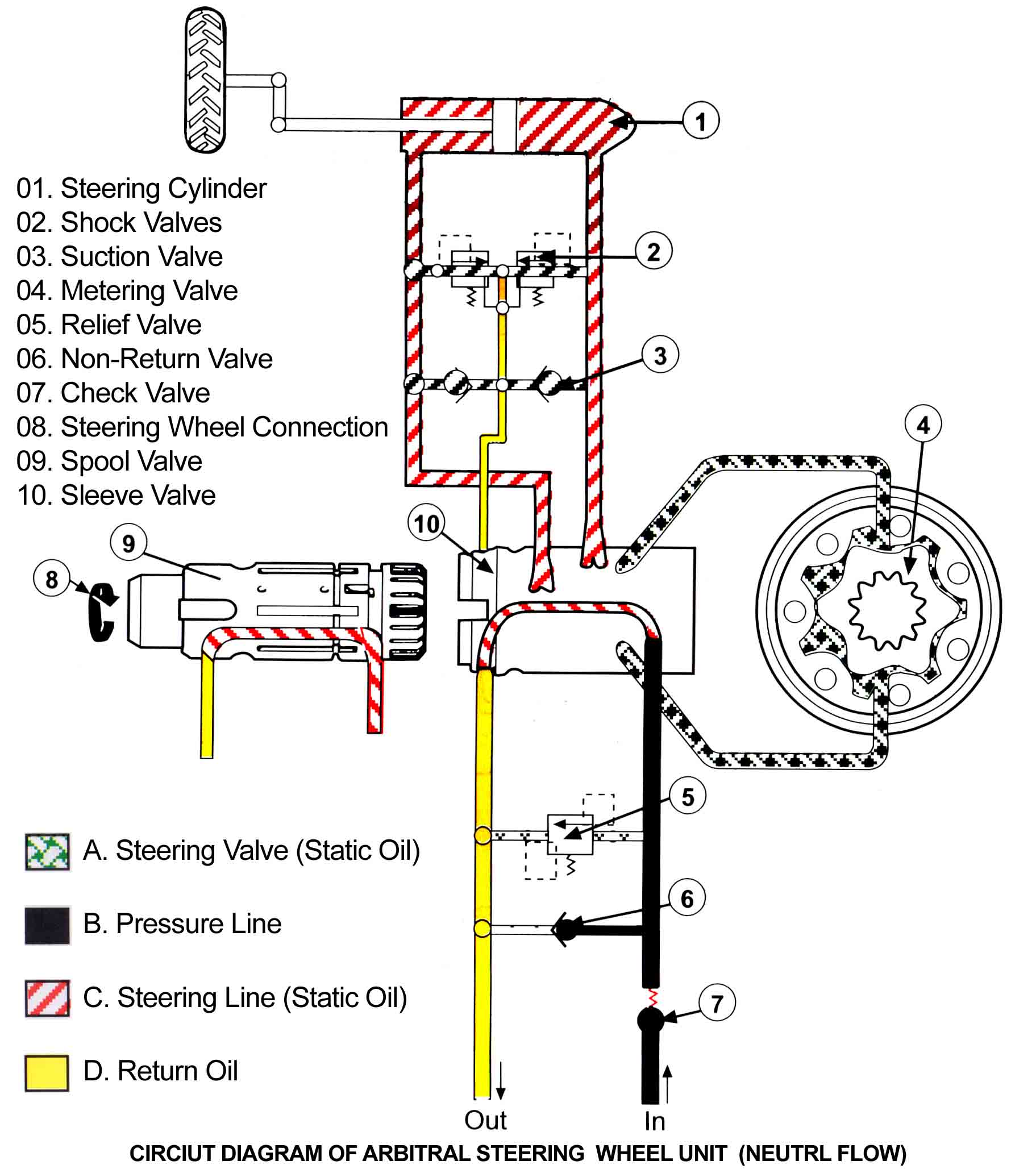

This system is installed in the MF385/385 4WD tractors, which allows the driver/operator to control the steering system with ease. Hydro-static power steering system is a complete power steering system in which there is no mechanical connection between the steering wheel and the front wheels, which allows the steering wheel to be turned with only one or two fingers. This tractor is especially suitable for working with front-end loaders. In this oil system is supplied to the steering control unit through steering pump, due to which controlled quantity of oil reaches the right and left sides by the steering cylinder when the steering wheel is turned; and when the steering wheel is straight, the steering unit bypasses the oil supply.

|

|

NOTE:Always use the reputable and reliable oil in MF350/260/375/385/385 4WD Tractors |

A. Neutral Oil Flow When Tractor is Moving Straight |

|

This is the neutral position of the steering unit. In this position the oil flows from the hydraulic pump to the steering unit, and because of the oil spool and sleeve hole being in straight position the oil returns to the steering pump. In this system two shock valves and two suction valves are fitted on the right and left sides of the steering unit. Shock valves are used between the steering rim cylinder and steering ring control unit to protect this system, whereas the suction valves are used to compensate any shortage of oil in the system.

|

|

|

CIRCUIT DIAGRAM OF ARBITRAL STEERING WHEEL UNIT (NEUTRAL FLOW)

|

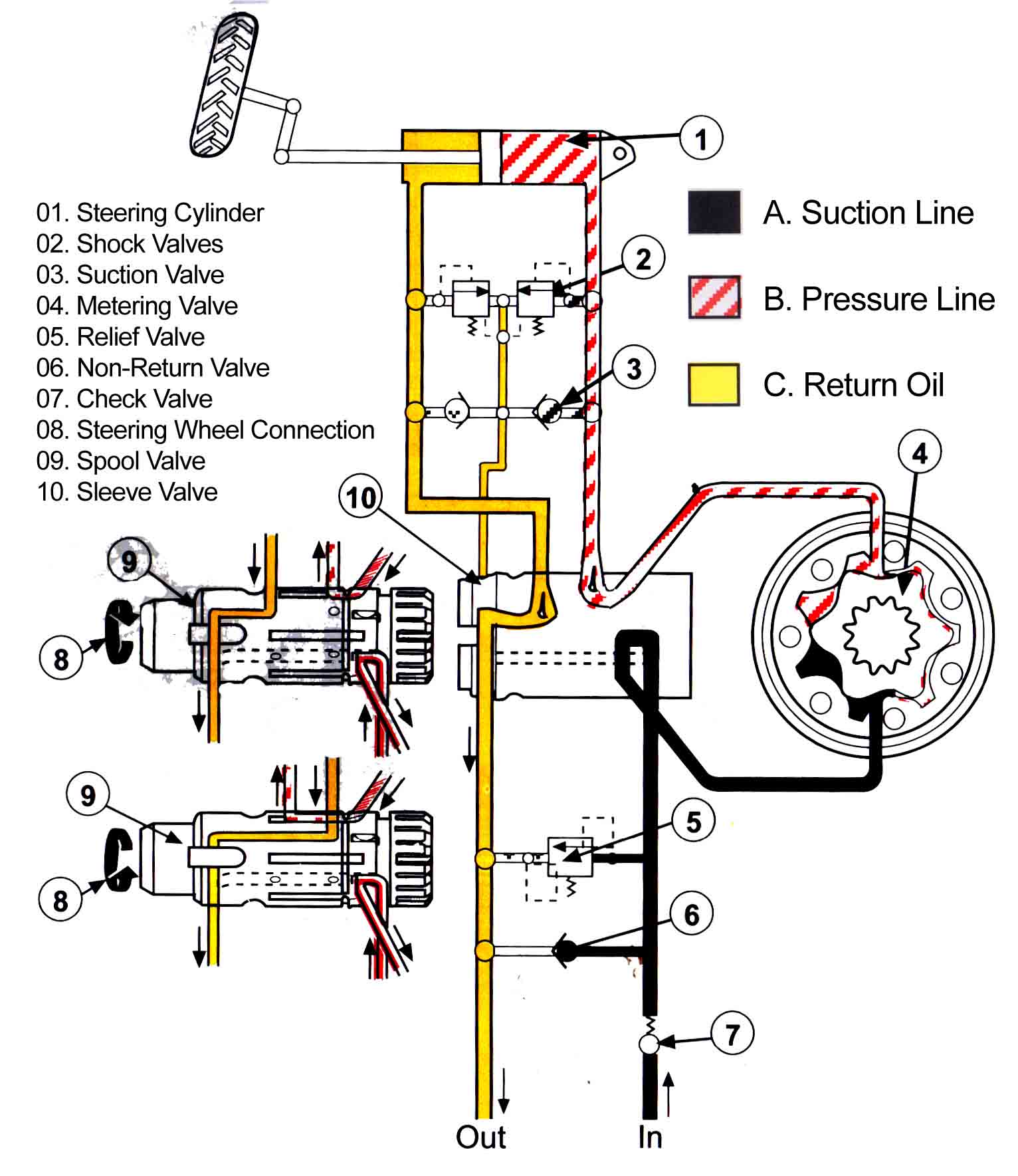

B. Turning of the Steering when the Engine is Running |

|

On first movement of the steering wheel the right and left turning holes become straight with each other, so that oil can be supplied to the oil hand pump. Subsequently, the second movement turns the steering and the hand pump. Simultaneously, the hand pump measures the quantity of oil and pushes it back towards the spool and sleeve. The oil coming back enters the spool valve through the grooves, which connect the holes together straightly so that the oil could go to the direction in which the steering wheel was turned. With the spool valve and sleeve holes being face to face with each other, the oil coming back from the steering cylinder returns to the circuit. The relief valve between the inlet and the spool inside the steering unit, which protects against the high-pressure created inside the pump, for example, due to an obstruction while the front wheels are turning. From the steering pump to the steering unit, there is a check valve installed on the way. This is a one-way valve that prevents high-pressure while the steering is being turned.

|

|

|

ORBITROL STEERING UNIT CIRCUIT (turning of the steering when the engine is running)

|

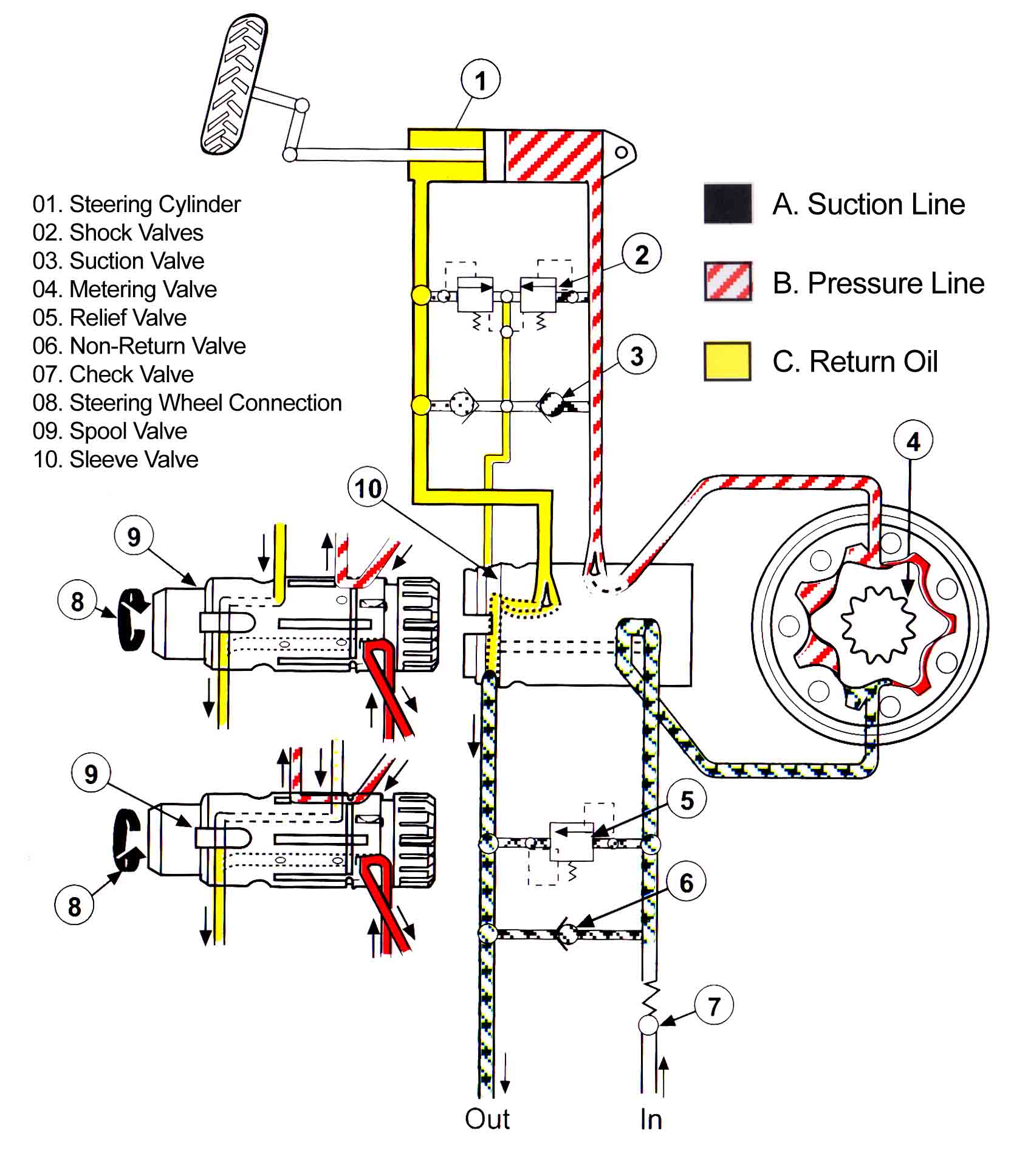

C. Turning the Steering when the Engine is OFF |

|

The pump stops working when the engine is turned off, due to which the oil starts to pass through a bypass valve installed inside the steering unit between the supply and return holes. As the pump starts to function, the oil pressure shuts off the valve by pushing it onto its seat. When the pump cylinder is low, the oil returning from the steering cylinder towards the valve inlet side is bypassed. With the help of this function, the oil can move from one side to the other inside the steering cylinder to maintain uninterrupted steering control.

|

|

|

ORBITROL STEERING UNIT CIRCUIT (turning of the steering when the engine is OFF)

|

Very Important

|

|

| MF-240/260/375 Provision for changing Transmission / Hydraulic oil | MF-385S/385 4WD Provision for changing Transmission / Hydraulic oil |

|

|

| Drain Plug | Drain Plug |

|

|

| Opening for filling the Oil MF-240/260/375S | Opening for filling the Oil MF-385/385 4WD |

Tractors PK is one of the top suppliers and exporters of Massey Ferguson Tractors and their compatible farm implements from Pakistan to across the globe including tractor models like MF-240 (50hp), MF-260 (60hp), MF-360 Turbo (60hp), MF-375 (75hp), MF-385 2WD and 4WD (85hp) at the lowest price. Usually, farming tractors used to pull a variety of farm implements to increase the farming process as well as the agriculture business.

We serve customers in Africa & the Caribbean region especially in Botswana, Ghana, Kenya, Nigeria, Uganda, Zambia, Zimbabwe, Tanzania, DR Congo, South Africa, Algeria, Sudan, Morocco, Angola, Ethiopia, Egypt,, Mozambique, Madagascar, Cameroon, Côte d’Ivoire, Niger, Burkina Faso, Mali, Malawi, Senegal, Chad, Somalia, Guinea, Rwanda, Benin, Burundi, Tunisia, South Sudan, Togo, Sierra Leone, Libya, Congo, Liberia, Central African Republic, Mauritania, Eritrea, Namibia, Gambia, Gabon, Lesotho, Guinea-Bissau, Equatorial Guinea, Mauritius, Eswatini, Djibouti, Comoros, Cabo Verde, Sao Tome & Principe, Seychelles, Barbados, Belize, Iraq, Saudi Arabia, Lebanon, Oman, Kuwait, Qatar, Cayman Islands, Dominican Republic, Guyana, Haiti, Jamaica, Antigua and Barbuda, Dominica, Grenada, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Sint Maarten, Suriname, Trinidad and Tobago, Turks, and Caicos, etc.

7A Queen’s Road, Lahore, Pakistan.

Phone: +92-320-2390-002 / +92-321-2390-002

Email: [email protected]

Website: https://www.tractorspakistan.com

Social Links:

https://www.facebook.com/TractorsPakistan

https://www.instagram.com/tractors.pk/

https://www.linkedin.com/company/tractorspk/

https://twitter.com/Tractorspk

https://www.youtube.com/user/Tractorspk

https://www.pinterest.com/Tractorsfrompakistan/

|

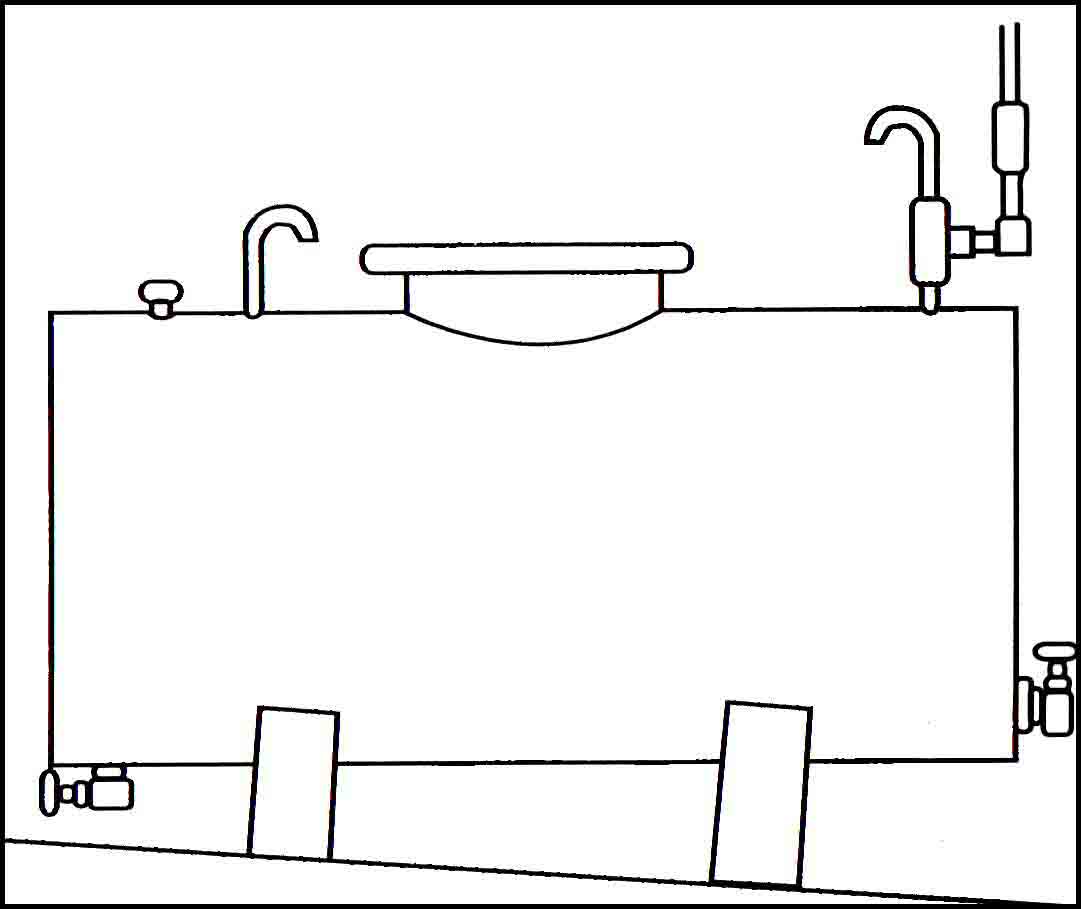

If diesel is to be stored in drums, then tilt the diesel filled drums as shown in the picture below. Front end of the drum must be 3 to 4 inches higher than its rear end, so that all unwanted deposits like sand, rust, dust settle at the back end, and clean diesel comes out from the front.

|

|

|

Storing the diesel on smaller scale

|

|

|

Storing the diesel on a larger scale

|

|

Always use uncontaminated diesel; i.e. that does not contain sand, water, kerosene, and other unnecessary elements, because these ruin the costly and delicate parts of the fuel injection pump and automizer which deteriorate engine performance. To protect the parts described and described above, it is important that you refill the diesel tank after completion of work. Refilling the tank will decrease air in it. The less air in the tank will create fewer water vapors, and the parts will be safe from harm. Never mix oil in the diesel. Diesel Inlets |

|

|

|

|

Massey Ferguson-260

|

Massey Ferguson-240/350

|

|

|

|

Massey Ferguson-375/385

|

Massey Ferguson-375/385 4WD

|

|

If air somehow enters fuel system of the tractor, it stops the fuel-supply and in turn stops the engine. This is called ‘engine is air-locked’. It is important to remove this air from the fuel system before restarting the tractor.

1. Reason for Air-Lock

2. How to Remove the Air-Lock

|

|

|

|

|

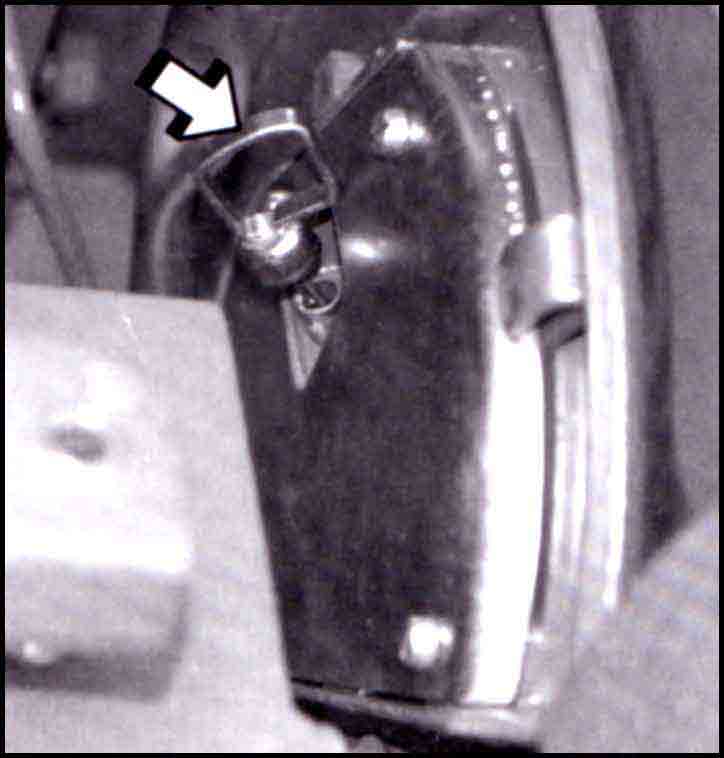

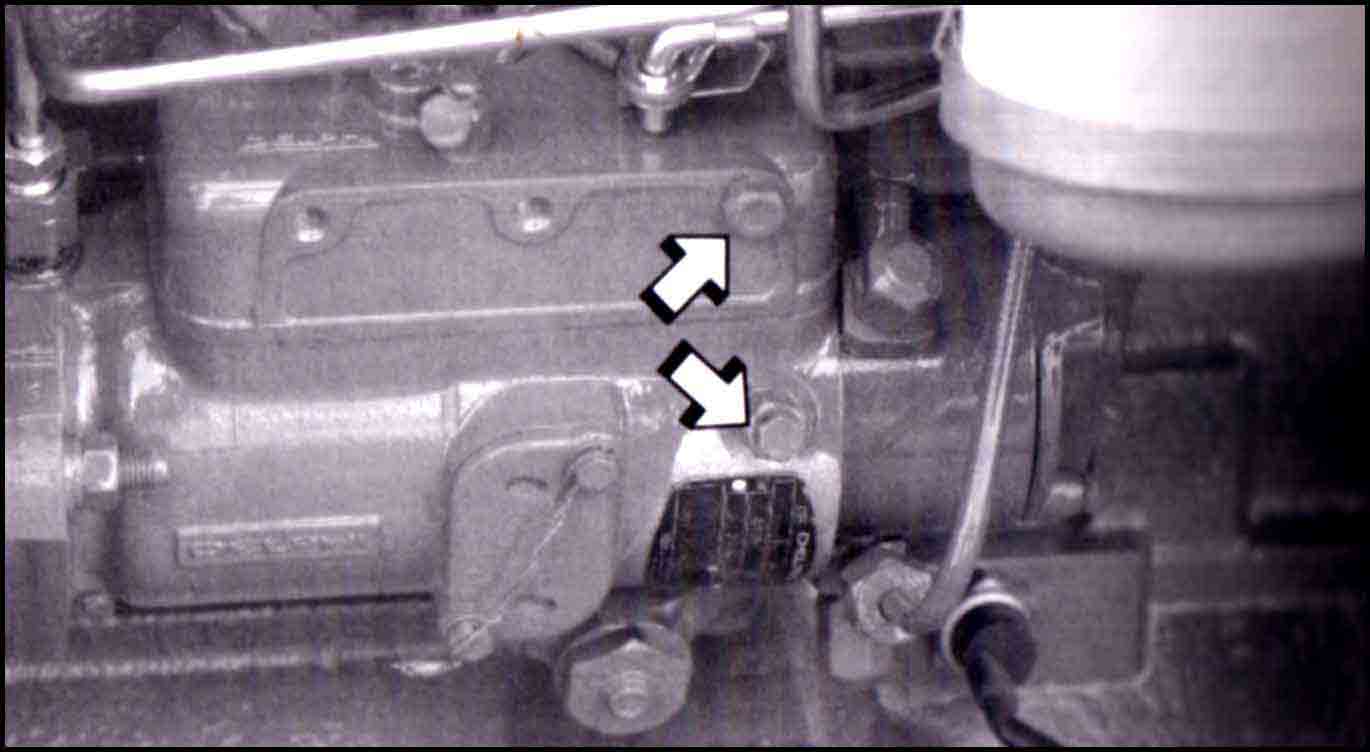

BLEEDING SCREWS MF-240/260/350

|

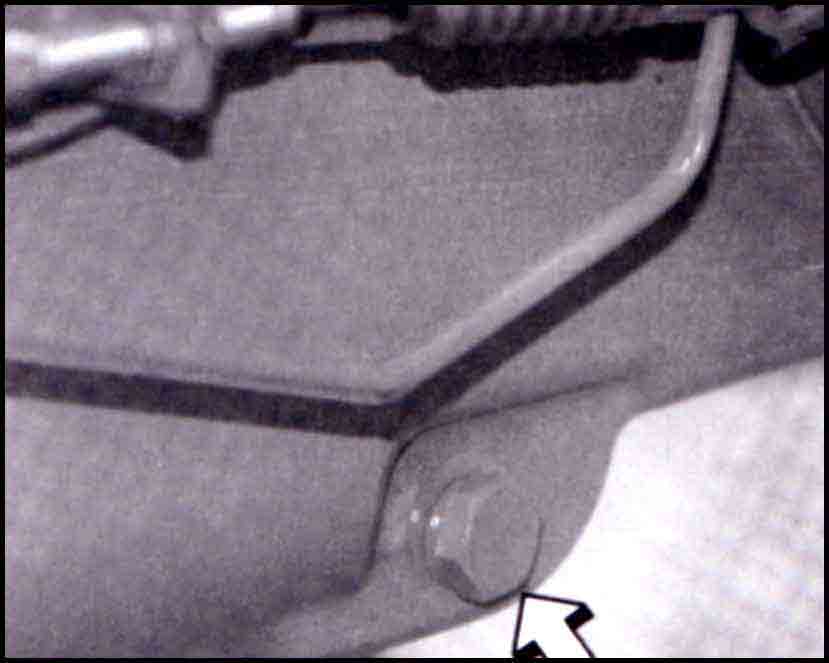

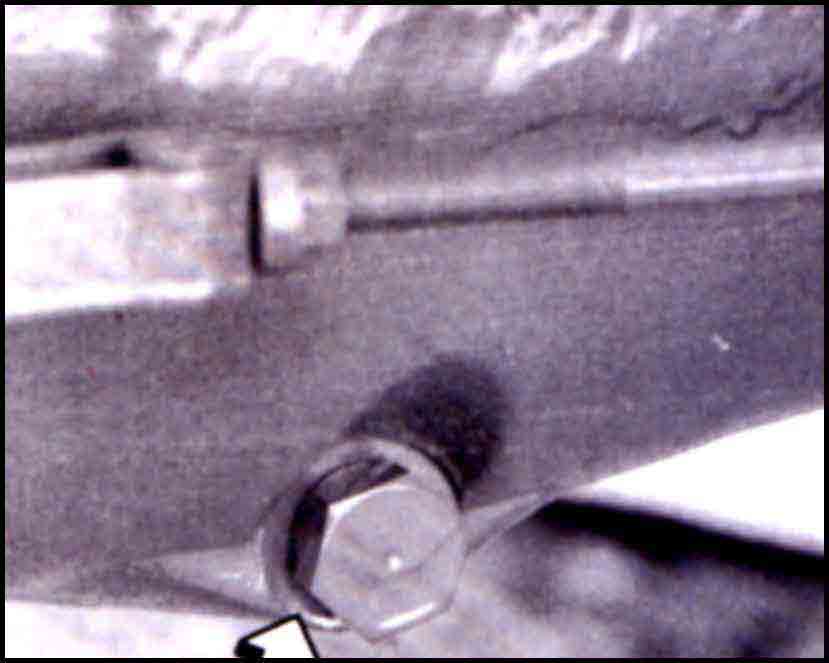

BLEEDING SCREWS MF-375S/385/385 4WD

|

|

|

|

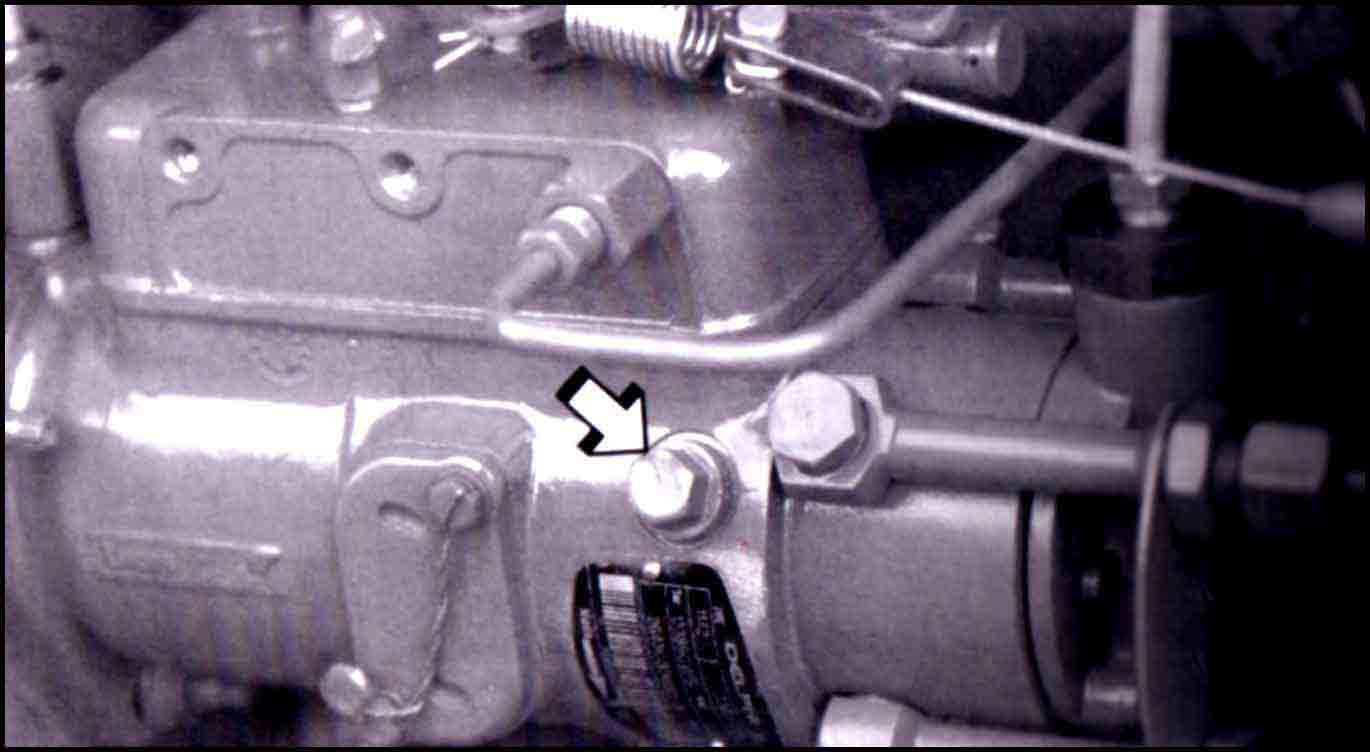

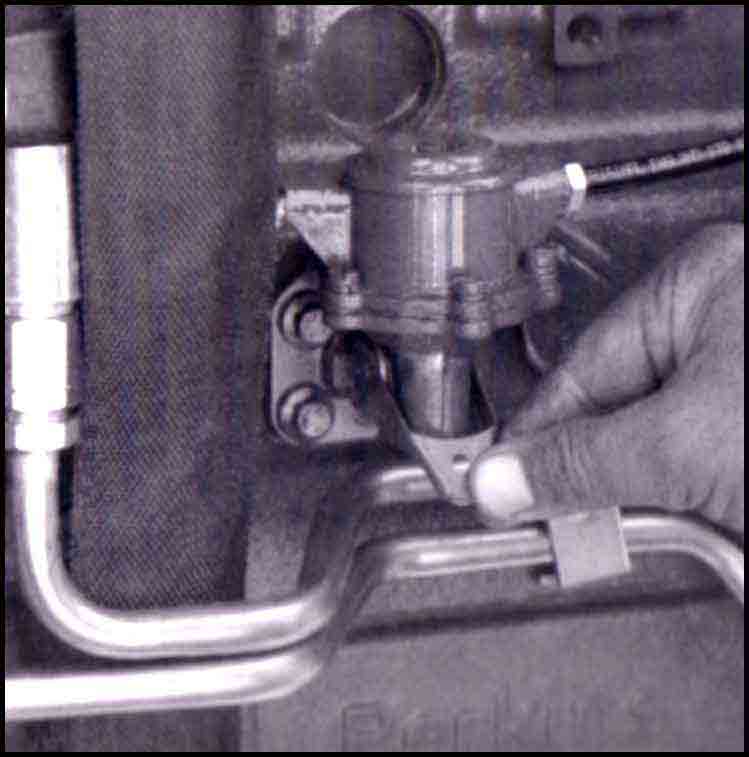

HAND PRIMING PUMP LEVER MF-240/260

|

HAND PRIMING PUMP LEVER MF-375/385

|

Tractors PK is one of the top suppliers and exporters of Massey Ferguson Tractors and their compatible farm implements from Pakistan to across the globe including tractor models like MF-240 (50hp), MF-260 (60hp), MF-360 Turbo (60hp), MF-375 (75hp), MF-385 2WD and 4WD (85hp) at the lowest price. Usually, farming tractors used to pull a variety of farm implements to increase the farming process as well as the agriculture business.

We serve customers in Africa & the Caribbean region especially in Botswana, Ghana, Kenya, Nigeria, Uganda, Zambia, Zimbabwe, Tanzania, DR Congo, South Africa, Algeria, Sudan, Morocco, Angola, Ethiopia, Egypt,, Mozambique, Madagascar, Cameroon, Côte d’Ivoire, Niger, Burkina Faso, Mali, Malawi, Senegal, Chad, Somalia, Guinea, Rwanda, Benin, Burundi, Tunisia, South Sudan, Togo, Sierra Leone, Libya, Congo, Liberia, Central African Republic, Mauritania, Eritrea, Namibia, Gambia, Gabon, Lesotho, Guinea-Bissau, Equatorial Guinea, Mauritius, Eswatini, Djibouti, Comoros, Cabo Verde, Sao Tome & Principe, Seychelles, Barbados, Belize, Iraq, Saudi Arabia, Lebanon, Oman, Kuwait, Qatar, Cayman Islands, Dominican Republic, Guyana, Haiti, Jamaica, Antigua and Barbuda, Dominica, Grenada, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Sint Maarten, Suriname, Trinidad and Tobago, Turks, and Caicos, etc.

7A Queen’s Road, Lahore, Pakistan.

Phone: +92-320-2390-002 / +92-321-2390-002

Email: [email protected]

Website: https://www.tractorspakistan.com

Social Links: https://www.facebook.com/TractorsPakistan

https://www.instagram.com/tractors.pk/

https://www.linkedin.com/company/tractorspk/

https://twitter.com/Tractorspk

https://www.youtube.com/user/Tractorspk

https://www.pinterest.com/Tractorsfrompakistan/